Aqueous

Premium centrifugal pumps

- Front-loaded Seal Design

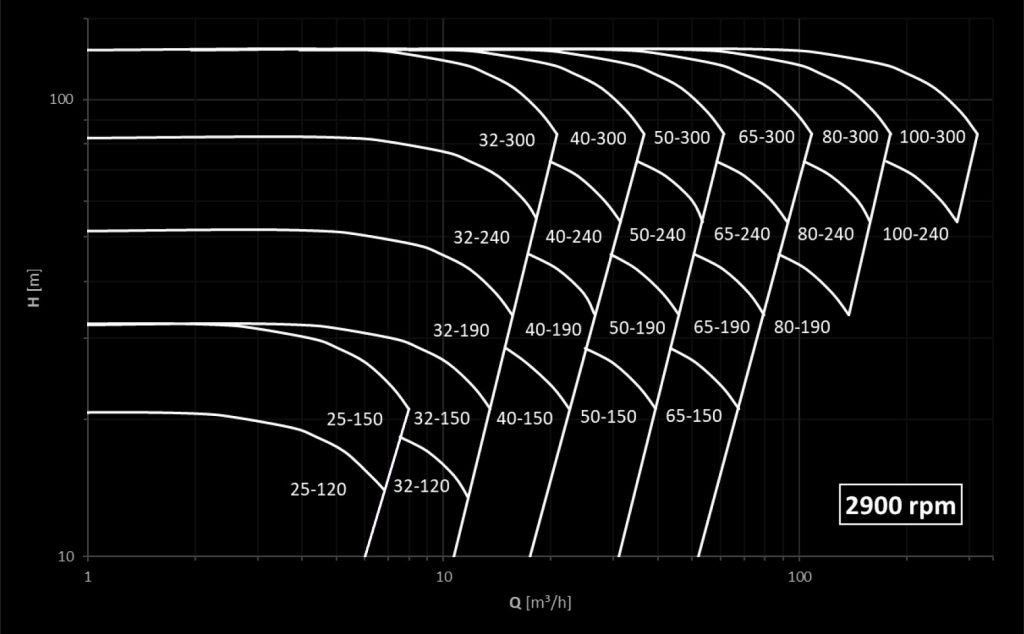

- Capacities up to 300 m3/h

- Conveying heights up to 120m

- Components in contact with the product in 1.4404

- optional 1.4435, 1.4539, 1.4462 and Hastelloy

- CIP- and SIP-cleaning procedures are possible without any restriction

- ATEX Zone 1 / 21

- Suitable for high system pressures

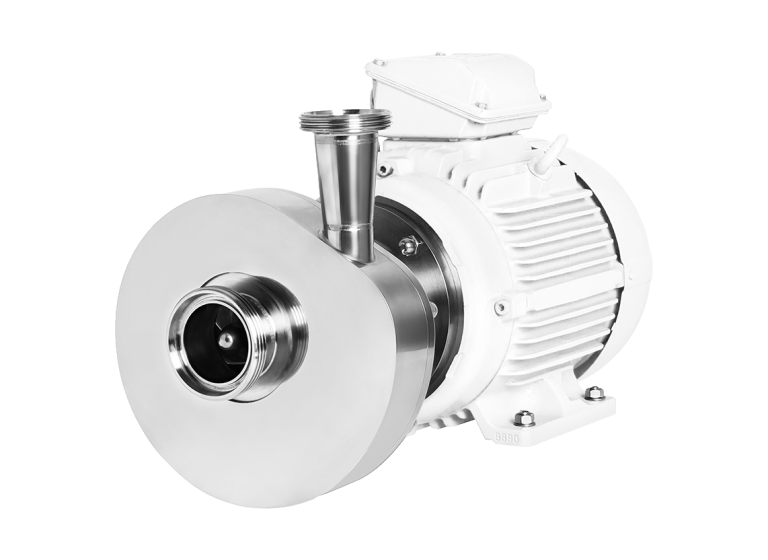

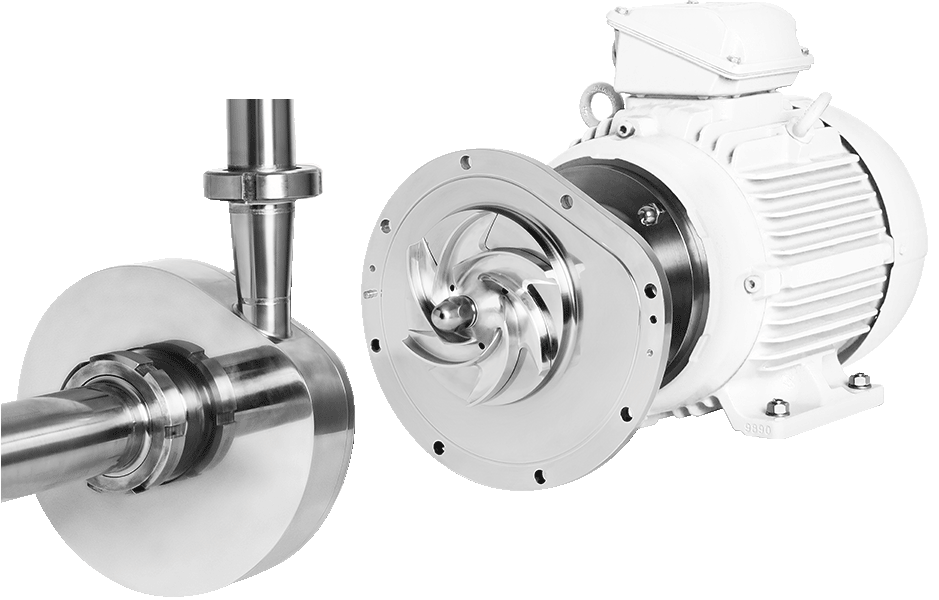

ipp Aqueous centrifugal pump

The individual customer solution

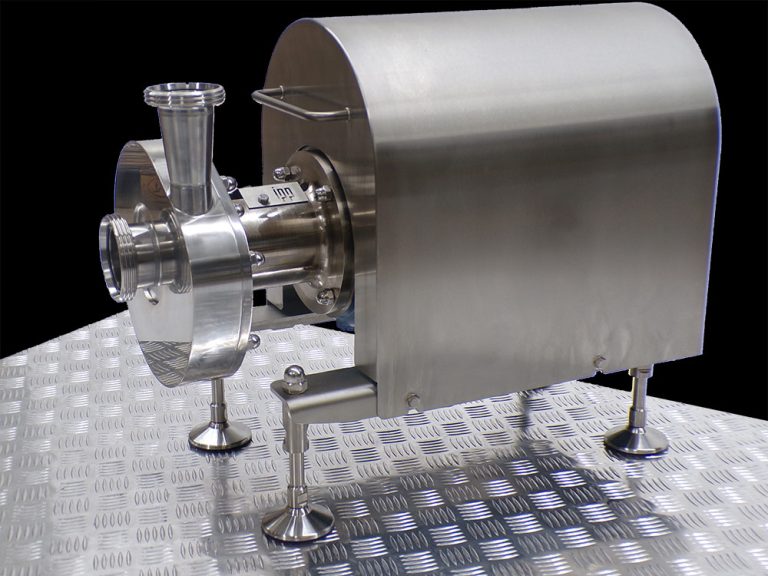

The coherent concept of the hygienic centrifugal pump Aqueous offers robust and durable operation in all applications. The complete machining of all parts from rolled material - including the impeller - is the basis for maximum stability, flexibility and high, consistent quality.

The modular design of the pump and mechanical seal ensures non-stop availability and a wide range of equipment options for customisation to meet the most difficult requirements. The use of stainless steel 1.4404 and FDA-compliant seals in areas in contact with the product are standard for us.

Surfaces and materials

- Standard 1.4404 (equivalent to AISI 316L) for metallic materials in contact with the product.

- 1.4435, 1.4539 and 1.4462 optionally (lowest delta-ferrit contents).

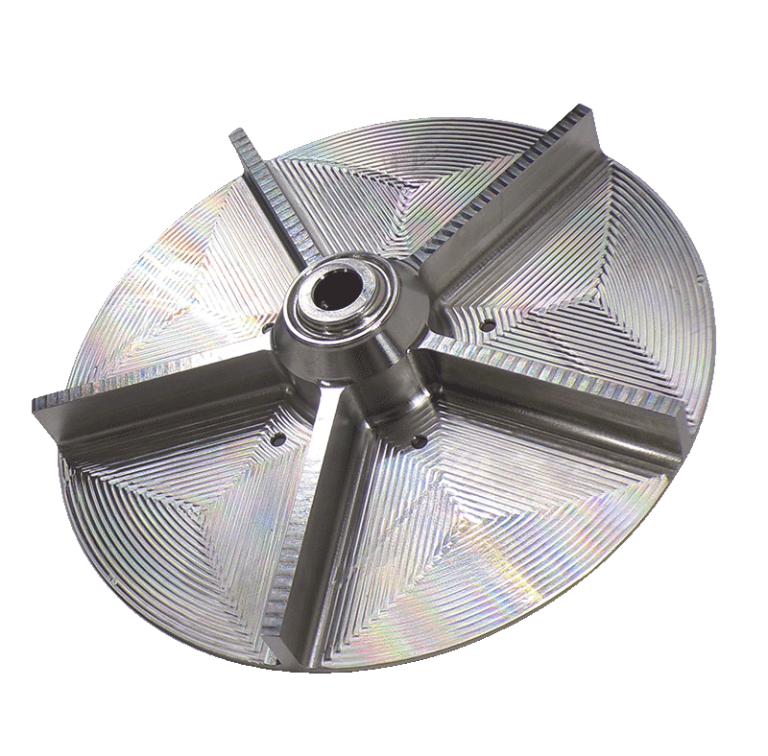

- Raw material always made from high-quality rolled steel.

- Cast materials are not used due to the risk of porosity.

- Special "cold" welding procedures are standard.

- Electropolishing and any surface roughness up to Ra<0.4 μm possible.

Technical concept

The components of the Aqueous centrifugal pump are machined from rolled material. This has decisive advantages over conventional pump systems. The standard surface quality of Ra≈0.8 ensures easy cleaning and therefore reliable processes and has a positive influence on efficiency. The dimensional accuracy ensures consistent quality in terms of the reproducibility of hydraulic operating points and rotational dynamics. Imbalances are reduced to a minimum by design.

At the same time, there are no dependencies with regard to cast or sheet metal semi-finished products, which results in maximum flexibility in terms of material selection and geometric requirements in order to meet the needs in the field.

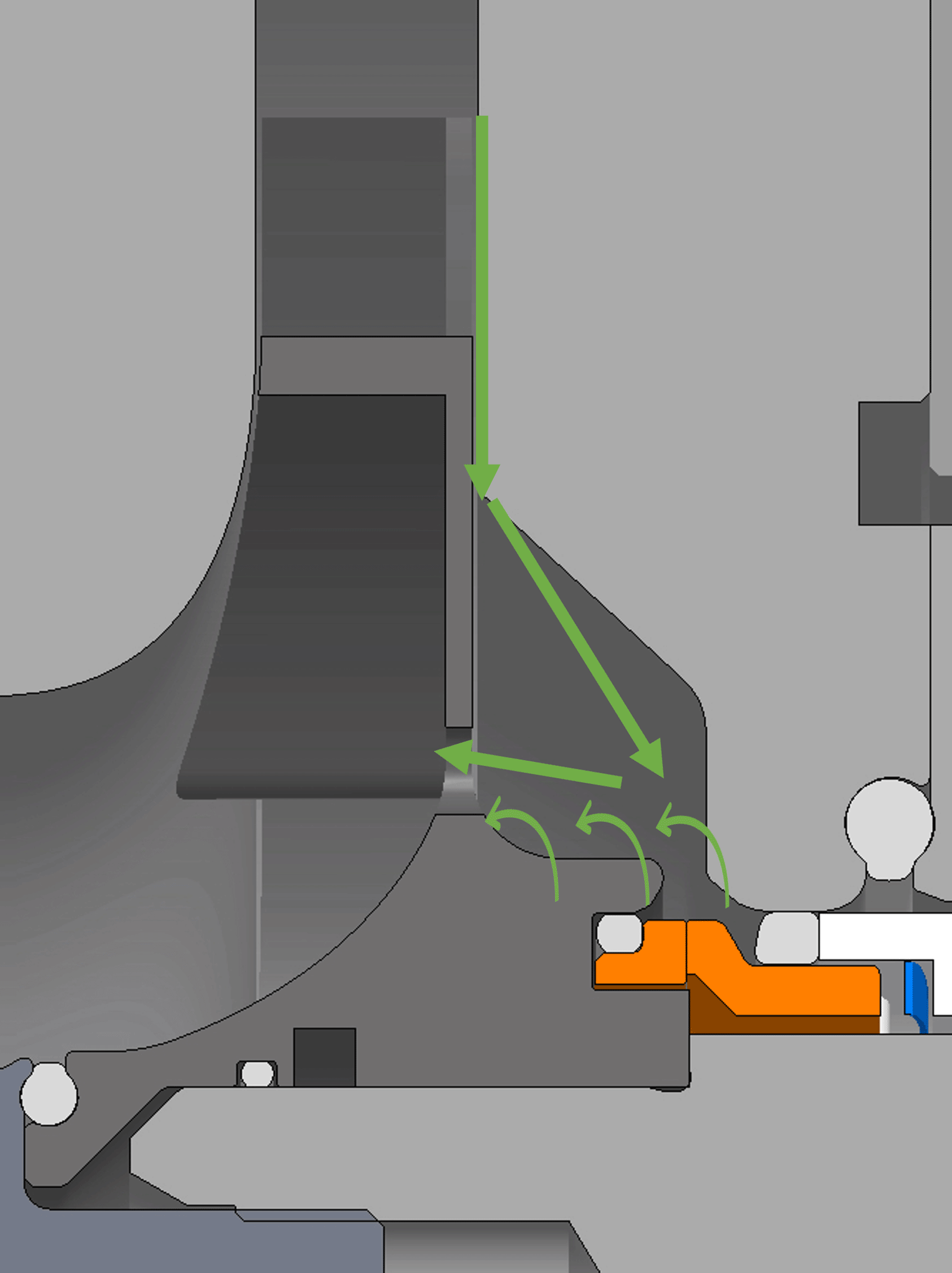

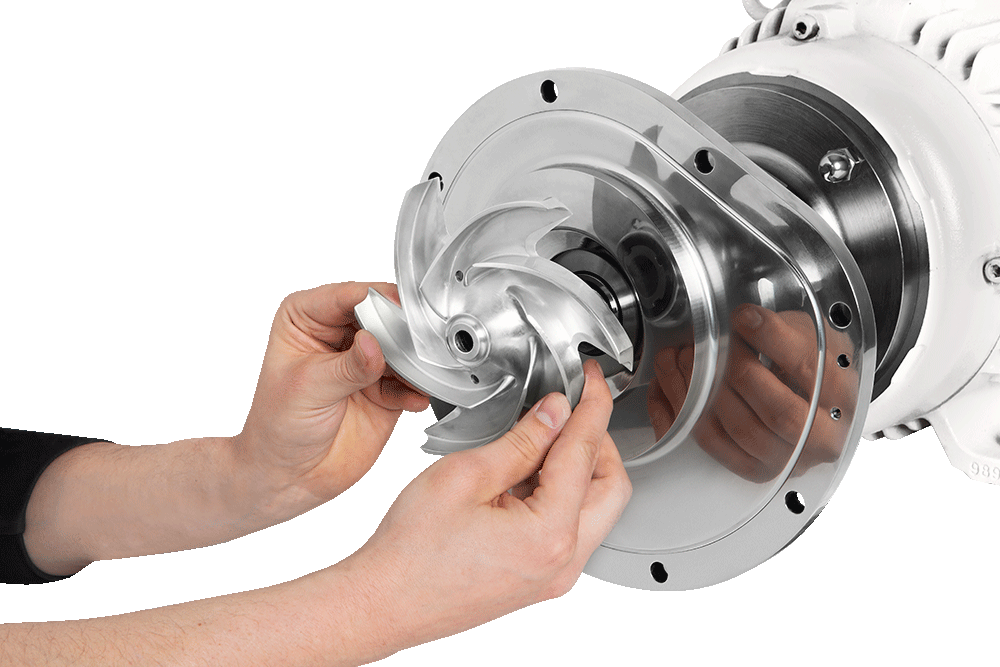

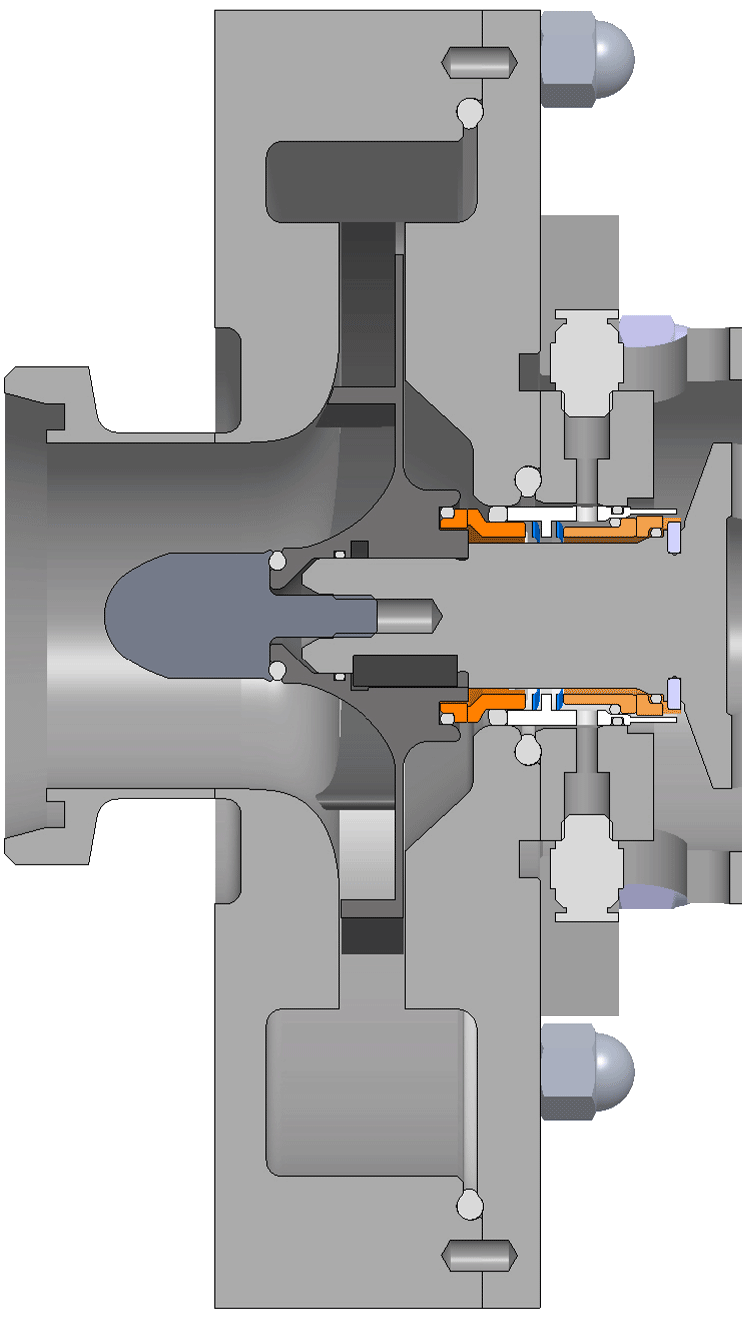

In the system, the hygienic centrifugal pump has a minimal footprint as a short block pump. For easy maintenance, the housing can remain connected to the pipework so that only the back pull-out unit (BPU) is retracted. All relevant parts are then accessible from the front.

Flexibility through modularity

The design of the pump takes into account the diverse requirements and, thanks to its modular construction, offers optional

- Large heat exchangers for cooling or heating in the immediate vicinity of the mechanical seal

- A variety of connections and their individual positions

- Drainage connection for complete residual draining

- Free-flow version for media with a high solids content

- Self-priming version for media with a high gas content

Hygiene is its strength

Free of residues through self cleaning (CIP / SIP)

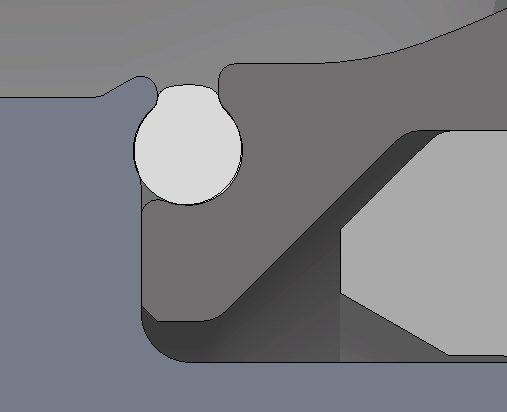

The pump can be cleaned without leaving any residue thanks to its hygienic design and O-rings pressed in without dead space (FDA standard; USP Class VI and other requirements possible), a key feature of which is that the mechanical seal is located in the pressure equalisation flow on the back of the impeller, which is a prerequisite for maximum hygiene and optimum temperature behaviour.

Shaft seals

Nonstop-availability due to "Front-Pull-Out"-system.

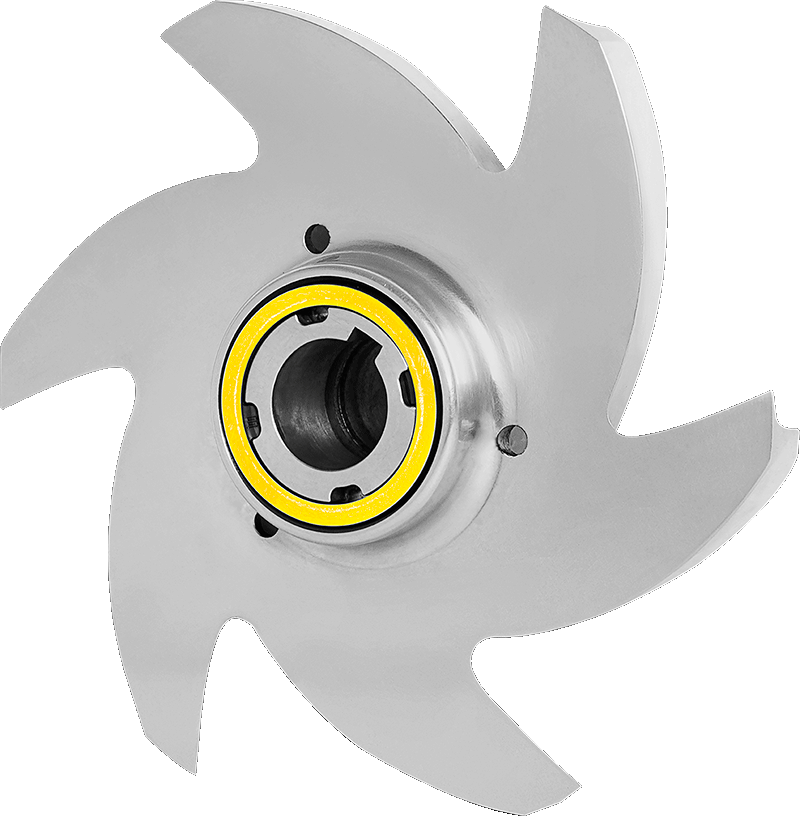

The modular design of the Aqueous series is particularly useful when it comes to seals. All the different standard sealing options are accessible from the front as a "front-pull-out principle" and can be interchanged at any time.

The choice between a single- or double-acting mechanical seal depends on many product and system-related criteria. Tungsten carbide is the first choice of mechanical seal ring material, with silicon carbide mechanical seal rings available as an option.

The secondary seals and elastomers in contact with the product can be made of NBR-FDA, Viton-FDA, EPDM-FDA or FFKM-FDA.

Applications

The right pump for any application

ipp centrifugal pumps can be used for all individual requirements and operating conditions: For water, WFI, cleaning media, beer, spirits, milk, vinegar, dressing, juices, syrups, lemonades, concentrates, oils, sauces, emulsions, solutions, acids, alkalis, ultrafiltration, alcohols, milk of lime.

Pumps for every application

Oils

Ipp pumps pump oils from low to high temperatures quietly and with low vibration. High efficiency minimises the influence of shear and heat on the product.

Dairy products

The high efficiency of the ipp pumps protects the product and saves energy. The aseptic design of the O-ring seals protects the quality of the medium and makes CIP cleaning of the pump quick and easy.

Juices & Beverages

With the high-tech products from ipp Pump Products GmbH, you can gently pump fruit juices, lemonades and other beverages. The option of a pressurised shaft seal makes it possible to pump products with a high sugar content.

Wine

Robust ipp pumps of the highest quality are ideal for conveying premium products in a contact-free, gentle and careful manner and ensuring quality during the process. Dry-run safe version available.

Beer

ipp pumps offer maximum reliability with smooth running. With a wide range of sizes and many options, the perfect pump can be selected to maintain a constant process with consistent quality.

Pharmacy

Process pumps for pharmaceutical and preliminary products must fulfil special requirements. GMP-compliant design is absolutely essential. ipp pumps are perfect for the gentle pumping of raw materials, WFI, vaccines, homeopathic products and plant extracts. All certificates and complete traceability of the materials in contact with the product are standard.

Characteristic diagram

Data refer to the pumped medium water at 20°C. In practice, the realisable values may be lower or higher, depending on the type of pumped product or the design of the system in which the pump is integrated. A precise and detailed analysis of the operating conditions is required for a conscientious design.

Contact person

M.Sc. Christoph Kuhlmann

Development Engineer

+49 5439 80921-0

Downloads

Here you can download further information on the ipp Aqueous centrifugal pump:

O-Ring Deckel-Gehäuse

O-Ring Deckel-Gehäuse