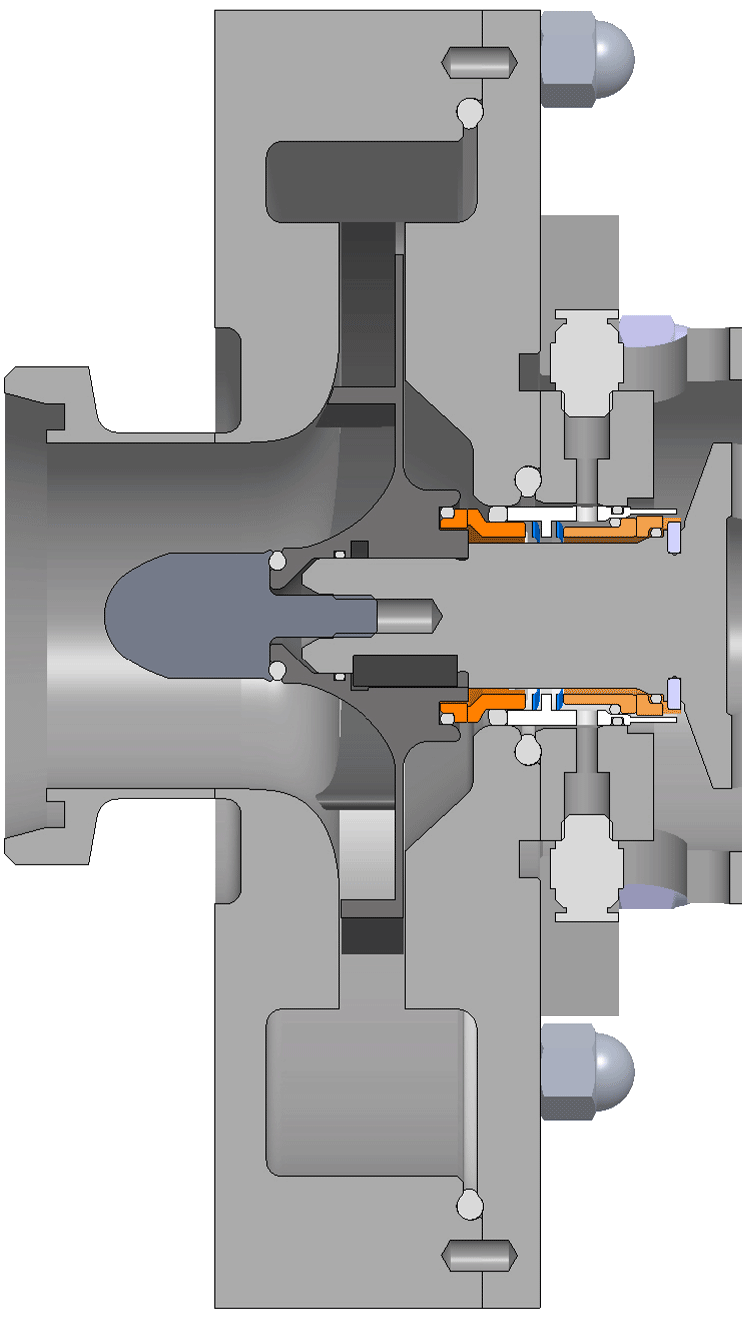

CIP/SIP cleaning - Centrifugal pump

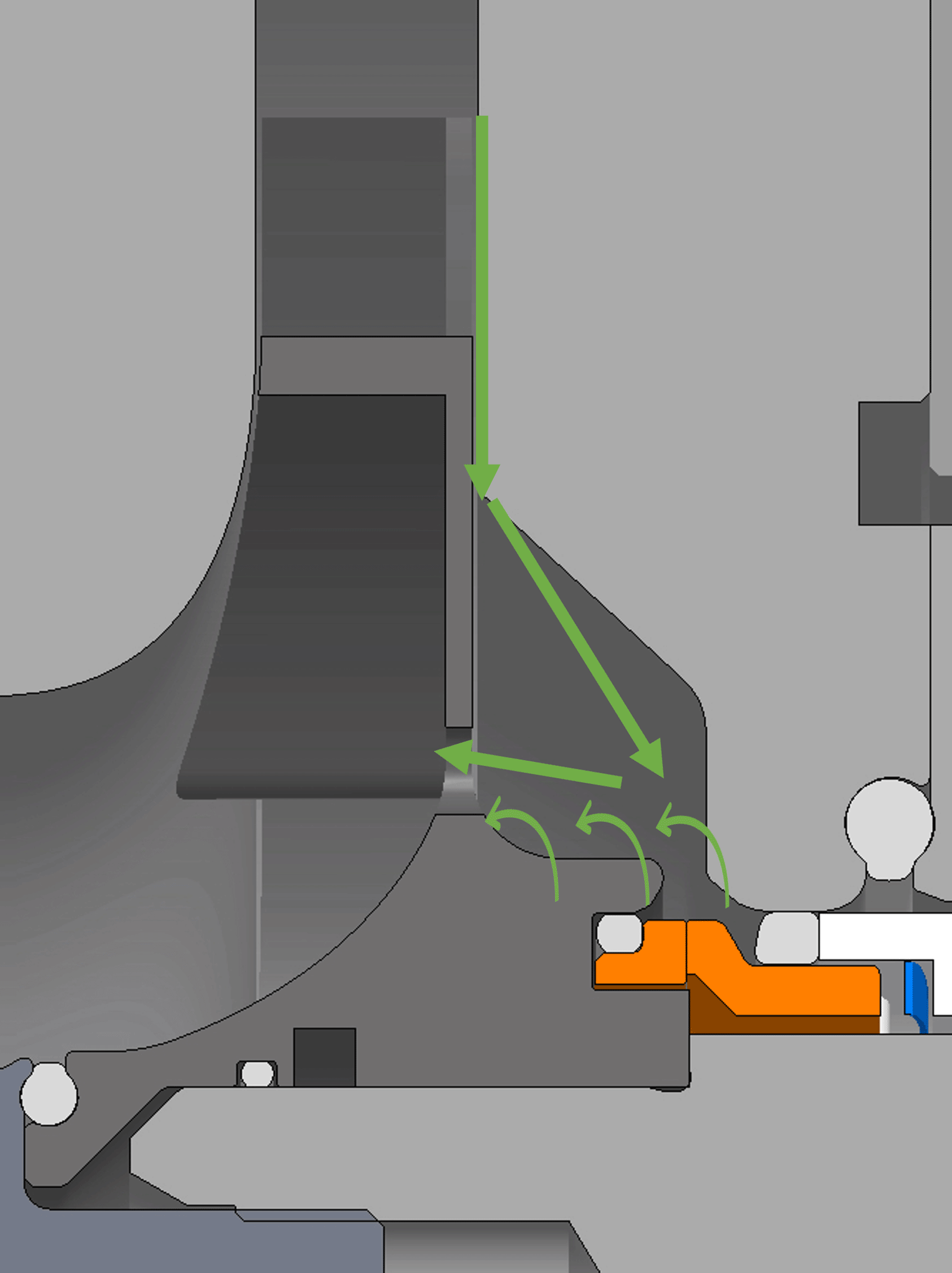

Free of residues through self cleaning (CIP / SIP)

CIP/SIP cleaning of the centrifugal pump ensures no residue thanks to the hygienic design and O-rings with no dead space. The mechanical seal is located in the pressure equalisation flow on the back of the impeller for maximum hygiene and temperature control.

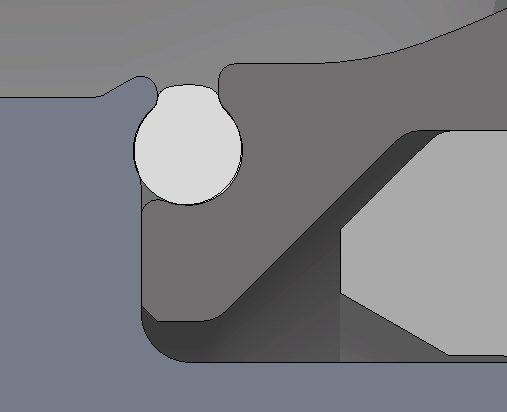

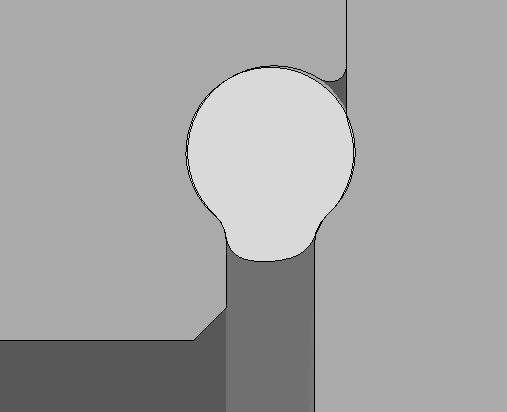

O-ring cover housing

O-ring cover housing