Aqueous centrifugal pump - ipp expands its product range

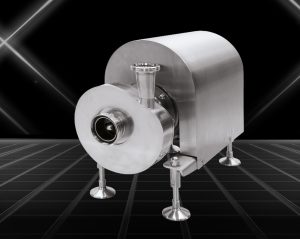

ipp Pump Products GmbH is expanding its range to include the Aqueous centrifugal pump. With its high flow rate, CIP and SIP capability and ATEX certification, it offers an ideal solution for low-viscosity media, for example in the food and pharmaceutical industries.

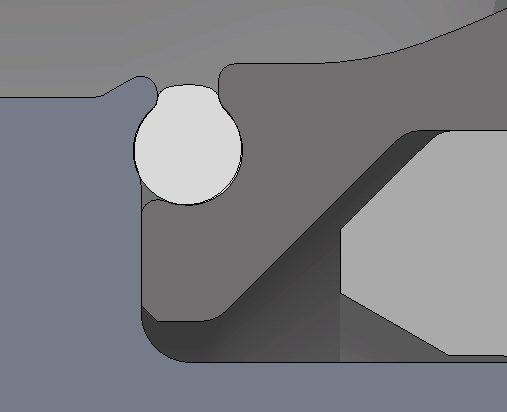

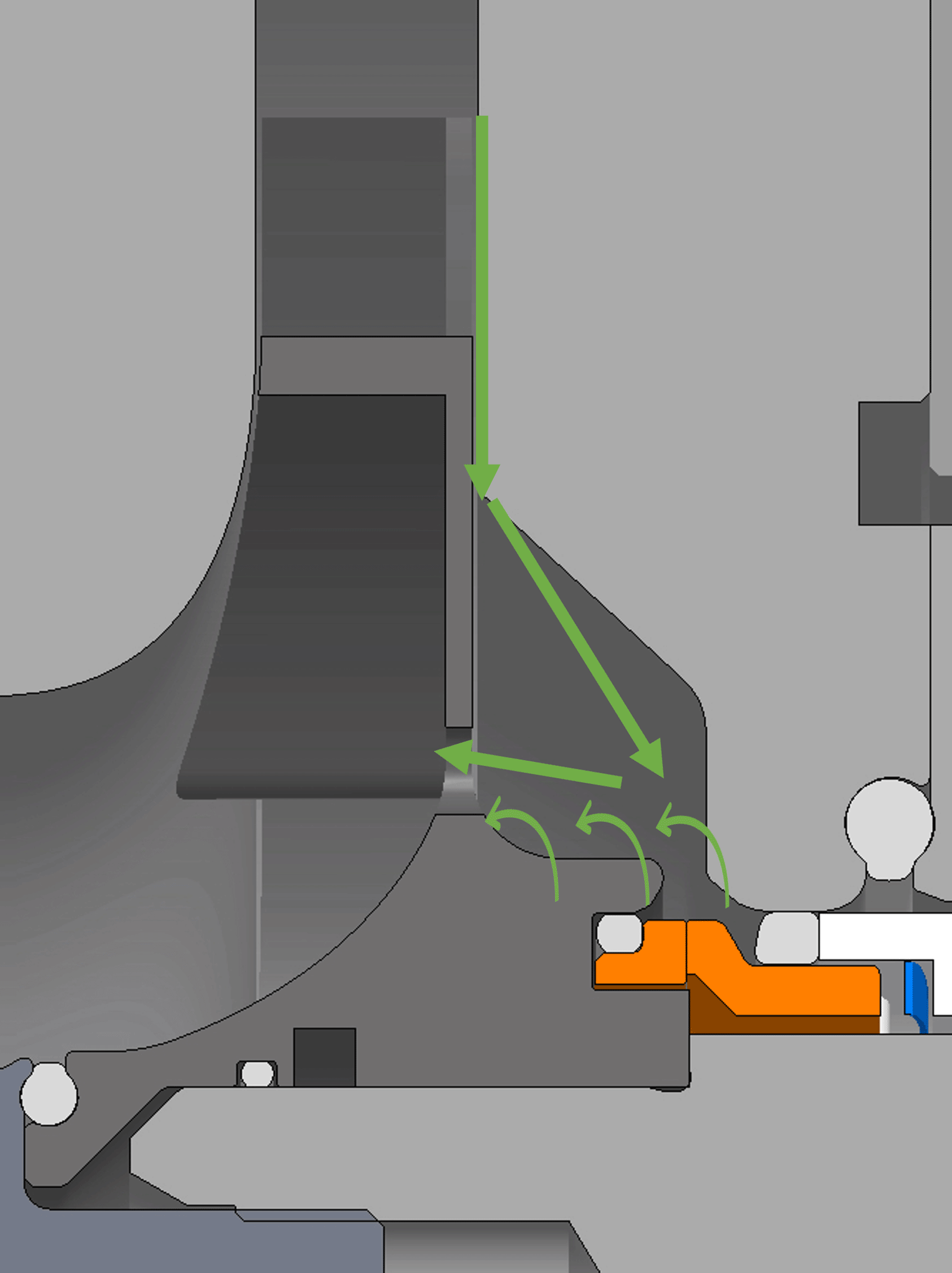

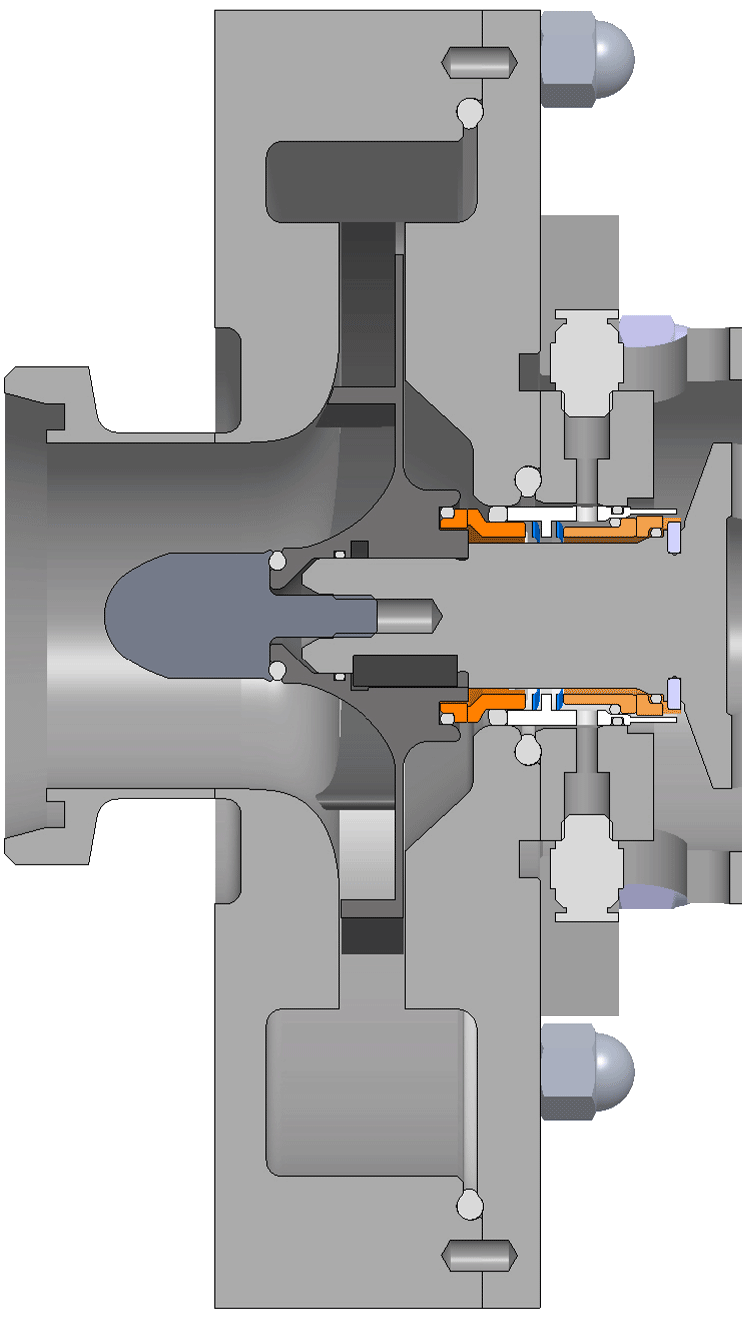

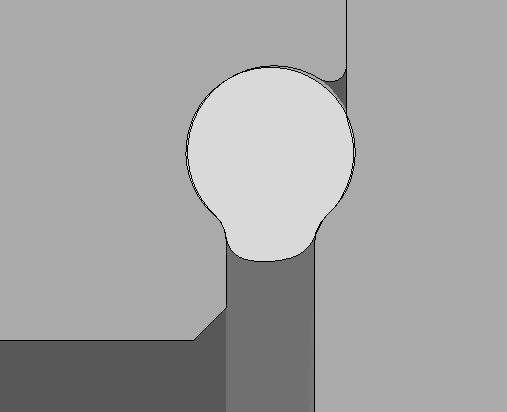

O-ring cover housing

O-ring cover housing