Worldwide distribution

ipp Distributors:

You are reseller, distributor or manufacturer and wish to complete your range with pumps from ipp Pump Products GmbH? We look forward to hearing from you.

Germany

ipp Pump Products GmbH

Feldmühlenweg 6 – 10

D-49593 Bersenbrück

Tel +49 5439 80921-0

Fax +49 5439 80921-20

Mr. Thomas Moldenhauer

info@pump-products.de

Feldmühlenweg 6 – 10

D-49593 Bersenbrück

Tel +49 5439 80921-0

Fax +49 5439 80921-20

Mr. Thomas Moldenhauer

info@pump-products.de

Netherlands / Belgium

ipp Pump Products GmbH

Feldmühlenweg 6 – 10

D-49593 Bersenbrück

Tel +49 5439 80921-0

Fax +49 5439 80921-20

Mr. Thomas Moldenhauer

info@pump-products.de

Feldmühlenweg 6 – 10

D-49593 Bersenbrück

Tel +49 5439 80921-0

Fax +49 5439 80921-20

Mr. Thomas Moldenhauer

info@pump-products.de

Switzerland

Trinox Engineering AG

Moosmühlestrasse 6

9000 St. Gallen

Tel +41-71-34445-55

Fax +41-71-34445-47

info@trinox.com

Poland

POMPY i SYSTEMY

ul. Kolibrów 4

02-818 Warszawa

Tel +48-22-5497940

Fax +48-22-5497950

Mr. Andrzej Bacinski

andrzej.bacinski@pompy.pl

ul. Kolibrów 4

02-818 Warszawa

Tel +48-22-5497940

Fax +48-22-5497950

Mr. Andrzej Bacinski

andrzej.bacinski@pompy.pl

India

SamTech Engineering Services Pvt. Ltd.

W9, Water Works Road, Thiru-Vi-Ka, Industrial Estate, Guindy

CHENNAI – 600032 Indien

Tel +91 044 2250 2230 / 2250 9473 /2250 4395 / 2250 4396

Mr. Ravi Shankar

ravishankar@samtechengg.in

USA / Canada

Heger Pumps, Inc.- ipp-Pumps

4141 Linden Ave

Long Beach, CA 90807 USA

Tel +1 562 9895432

Fax +1 562 9892031

Mr. Siegfried J. Heger

sheger@hegerpumps.com

France

DKF POMPE

24 rue Robert Desnos

69120 – VAULX EN VELIN – France

Tel + 33 (0)4 37 45 39 82

Fax +48-22-5497950

24 rue Robert Desnos

69120 – VAULX EN VELIN – France

Tel + 33 (0)4 37 45 39 82

Fax +48-22-5497950

Turkey

KNT Endüstri Ekipmanları ve Pompa Sistemleri

Yeşilköy Mh. Atatürk Cd. EGS Business Park B2 Blok No:12/1

34149 Bakırköy, Istanbul Türkei

Tel +90 212 982 3944

Mobil +90 541 711 2236

Fax +90 850 522 3403

Mr. Bakım ve Onarım Hizmetleri

info@kntendustri.com

Contact person

B.Sc. Michael Krone

Technical support

+49 5439 80921-0

mkrone@pump-products.de

Contact person

Christiane Schimpfky

Shipping & Distribution

+49 5439 80921-0

Call now directly

ipp is international

ipp Pump Products GmbH is represented at a number of international trade fairs, exhibitions and congresses. Please find below an overview of all fairs and events.

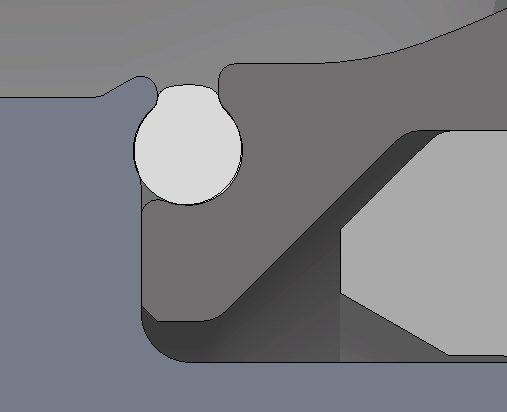

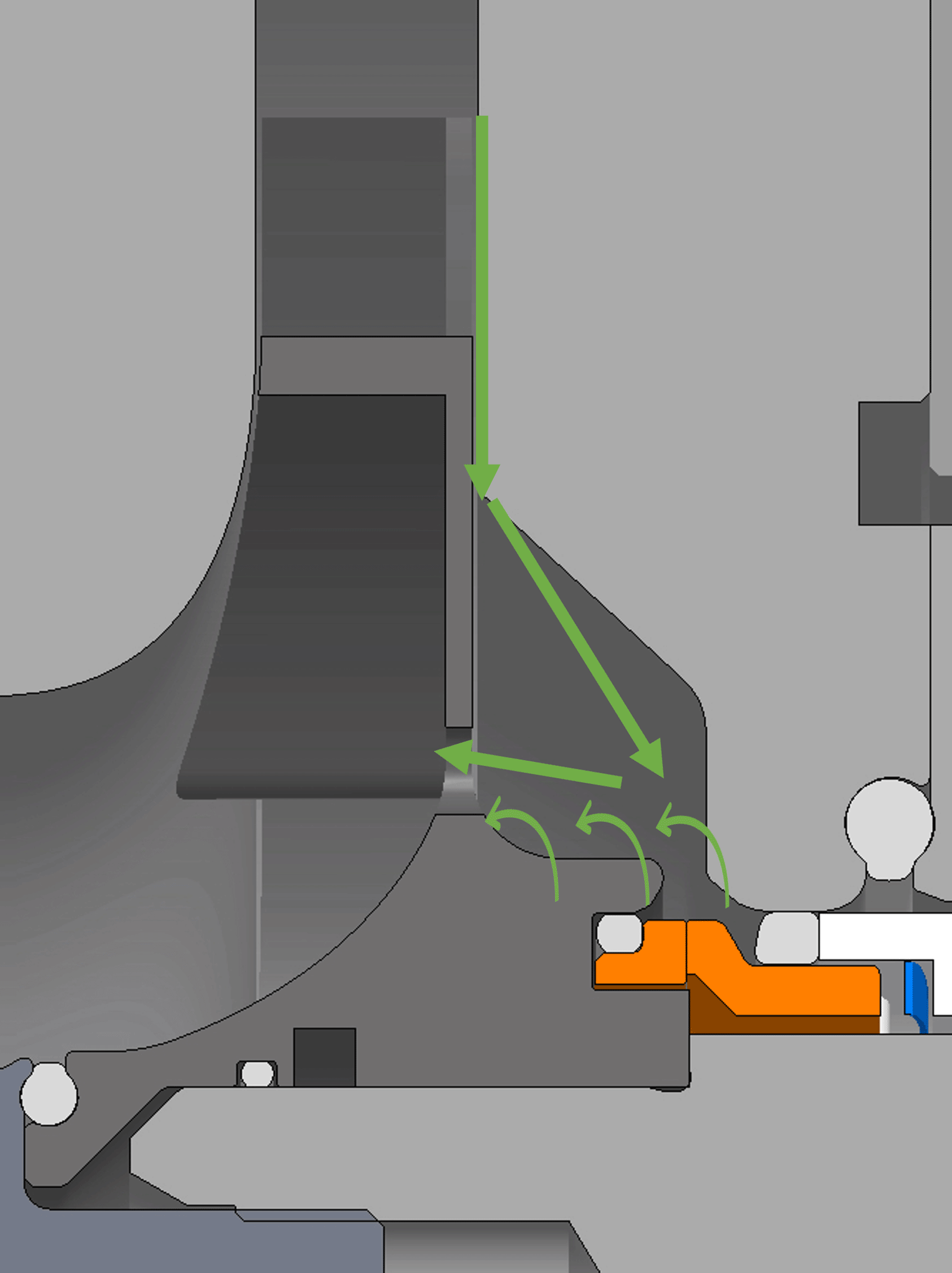

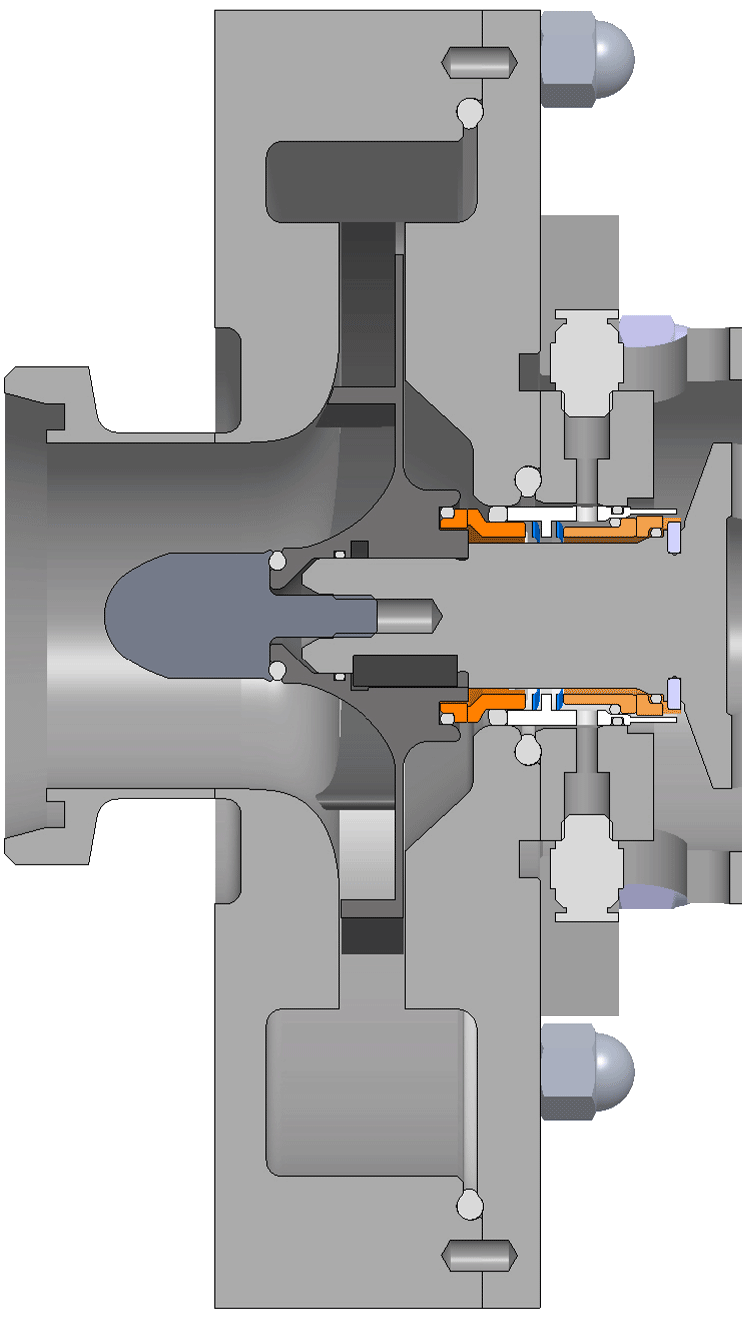

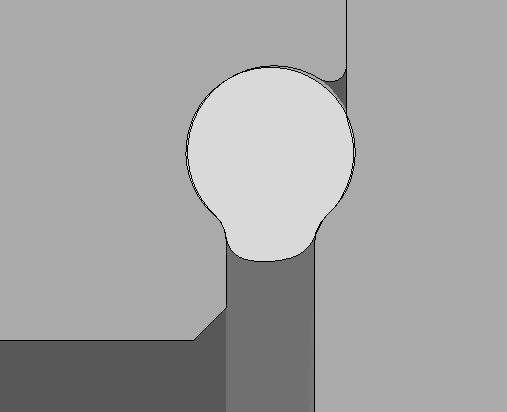

O-ring cover housing

O-ring cover housing