Quality

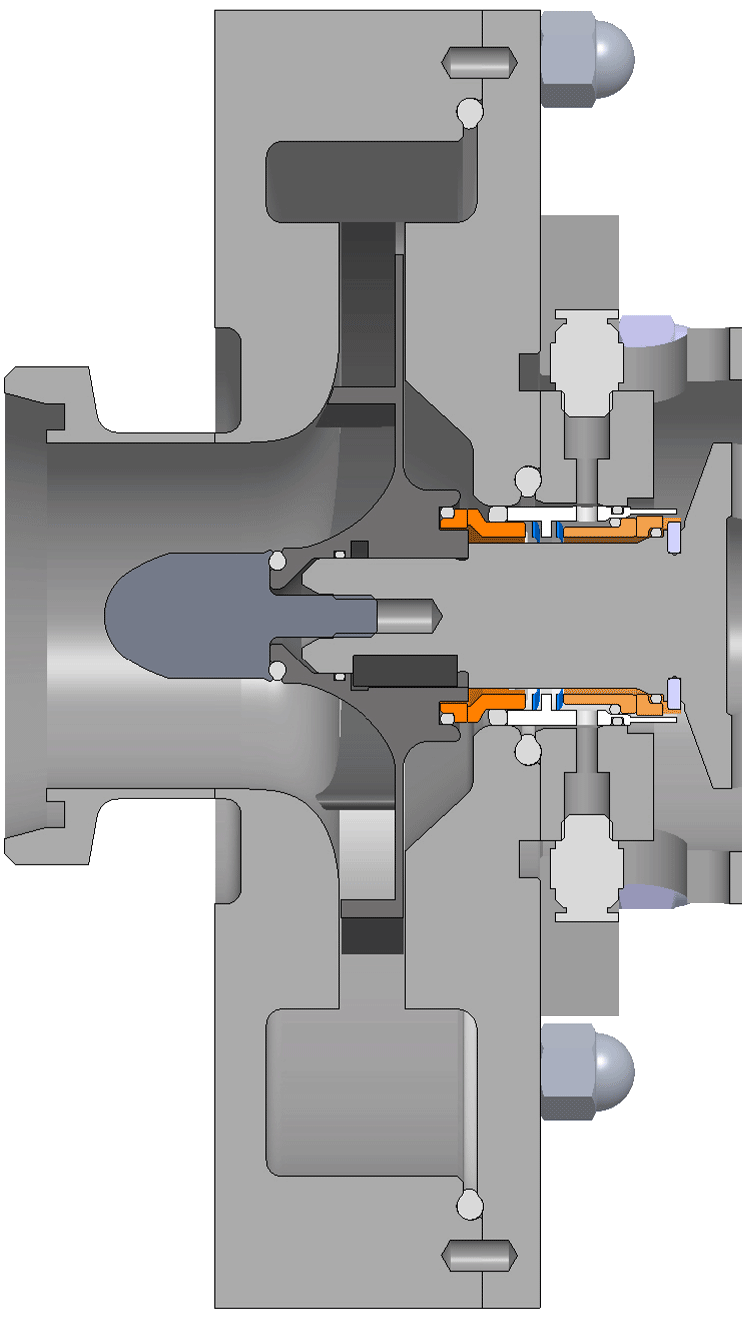

Premium material and manufacturing process

ipp Pump Products GmbH use state-of-the-art processes and equipment of the machining technology to manufacture all important components of the pump from solid. We create a tailor made solution for your application: From the analysis of the process and planning up to a worldwide after-sales service. We offer highest process safety and reliability, low life cycle cost, little wear and tear, best efficiency as well as compliance with international standards like ISO 9001:2015, EHEDG or restamping authorization with TÜV Nord.

Certified according to

new ISO 9001:2015

ipp Pump Products GmbH is certified in compliance with ISO 9001:2015 in the field of development, production, sales and service of rotary lobe pumps and related pumps

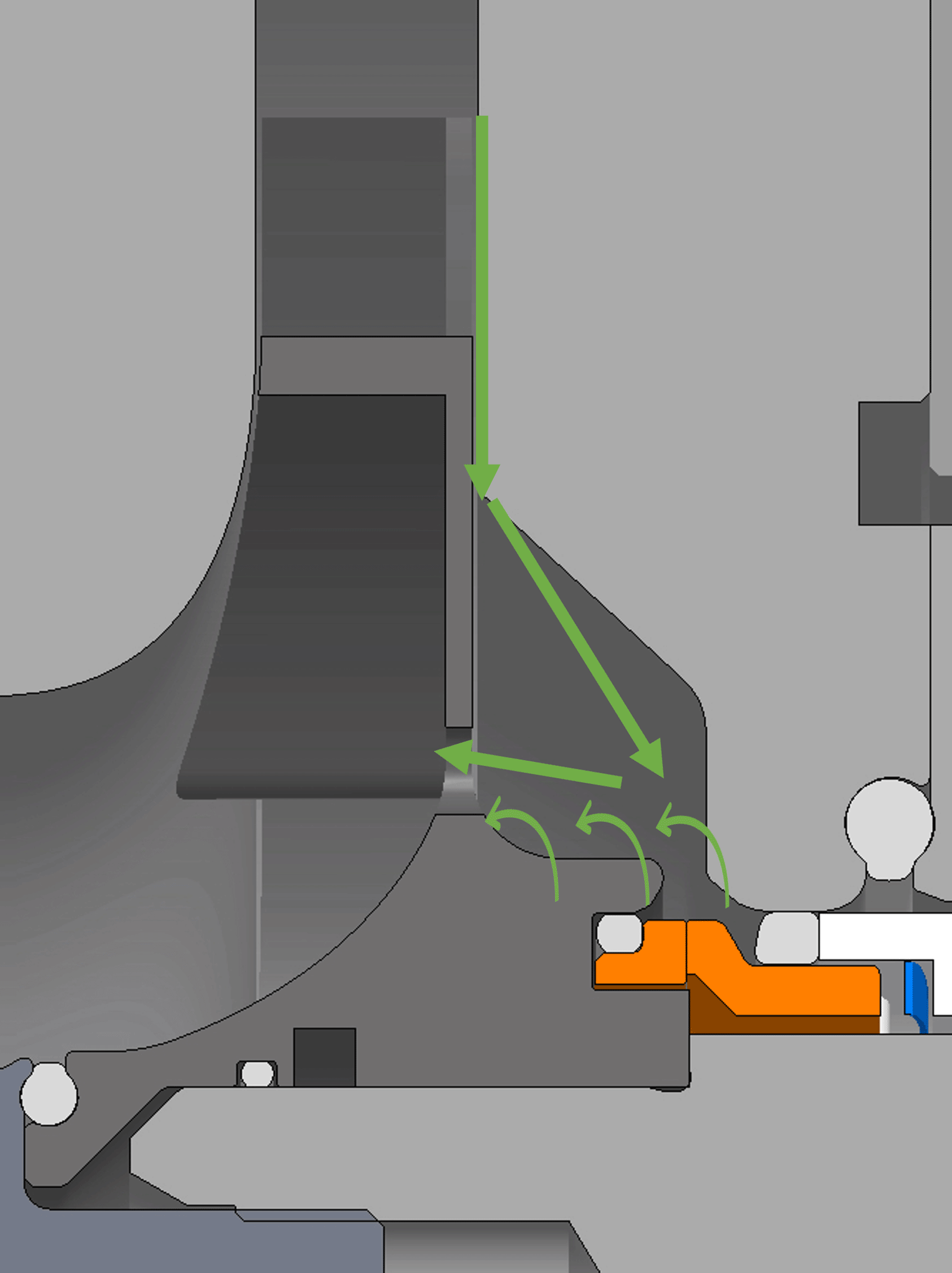

European Hygienic Engineering & Design Group

The European Hygienic Engineering & Design Group (EHEDG) is an expert consortium of equipment manufacturers, experts from food producers as well as research institutes and public health authorities. The group was founded in 1989 with the principle goal to strengthen the awareness of hygienic manufacturing and packaging of food.

TÜV Nord

ipp is authorized by the TÜV NORD to restamp materials.

Contact person

Dipl.-Ing. (FH) Walerij Stein

Development / Quality Control/ Technical Management

+49 5439 80921-0

TÜV Nord

ipp is authorized by the TÜV NORD to restamp materials.

Certified according to new ISO 9001:2015

ipp Pump Products GmbH is certified in compliance with ISO 9001:2015 in the field of development, production, sales and service of rotary lobe pumps and related pumps

European Hygienic Engineering & Design Group

The European Hygienic Engineering & Design Group (EHEDG) is an expert consortium of equipment manufacturers, experts from food producers as well as research institutes and public health authorities. The group was founded in 1989 with the principle goal to strengthen the awareness of hygienic manufacturing and packaging of food.

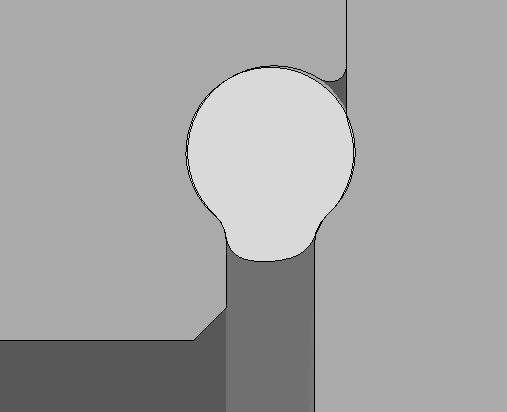

O-ring cover housing

O-ring cover housing