News - ipp Pump Products

We are constantly developing ourselves and our products

POWTECH Technopharm 2025

The international trade fair for technologies for processing powders, solids and liquids.

September 23-25, 2025

Hall 10.0 | Booth 10-328

ProSweets 2026

the international supplier fair for the confectionery and snack industry in Cologne!

01.-04.02.2026

Contact person

Thomas Moldenhauer

Managing Director

+49 5439 80921-0

Call Thomas Mldenhauer directly.

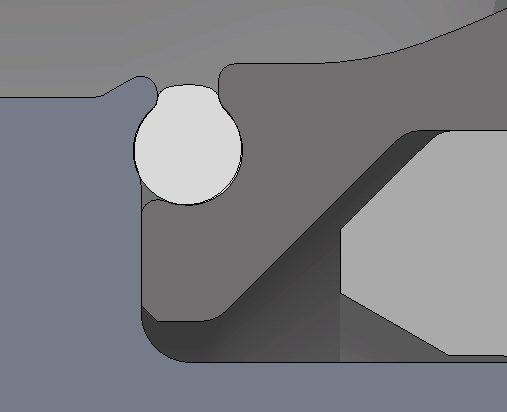

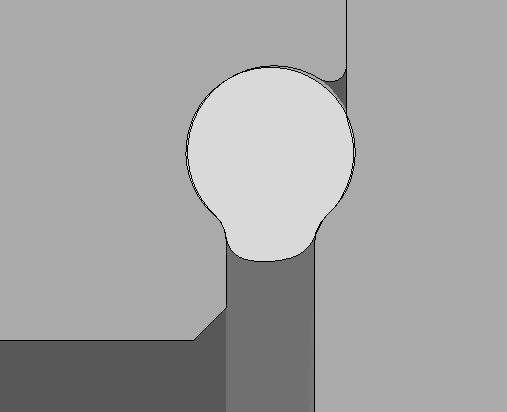

O-ring cover housing

O-ring cover housing