Visit us at ProSweets

The international supplier fair for the confectionery and snack industry.

28. bis 31. Januar 2024

Hall 10.1 | Booth: E050

Anuga FoodTec 2024

Visit us at Anuga 2024 in Cologne. From March 19-22, 2024 in hall 4.1 | booth B-070

ACHEMA 2024

Visit us at the ACHEMA in Frankfurt am Main. From June 10-14, 2024 in hall 8.0 | booth E80

Current job advertisements

ipp Pump Products is looking for reinforcement:

- Engineer

Design & Development Pumps

- Sales professional

- Office Manager

- Fitter

We look forward to receiving your application.

Hier erhalten Sie weitere Infos:

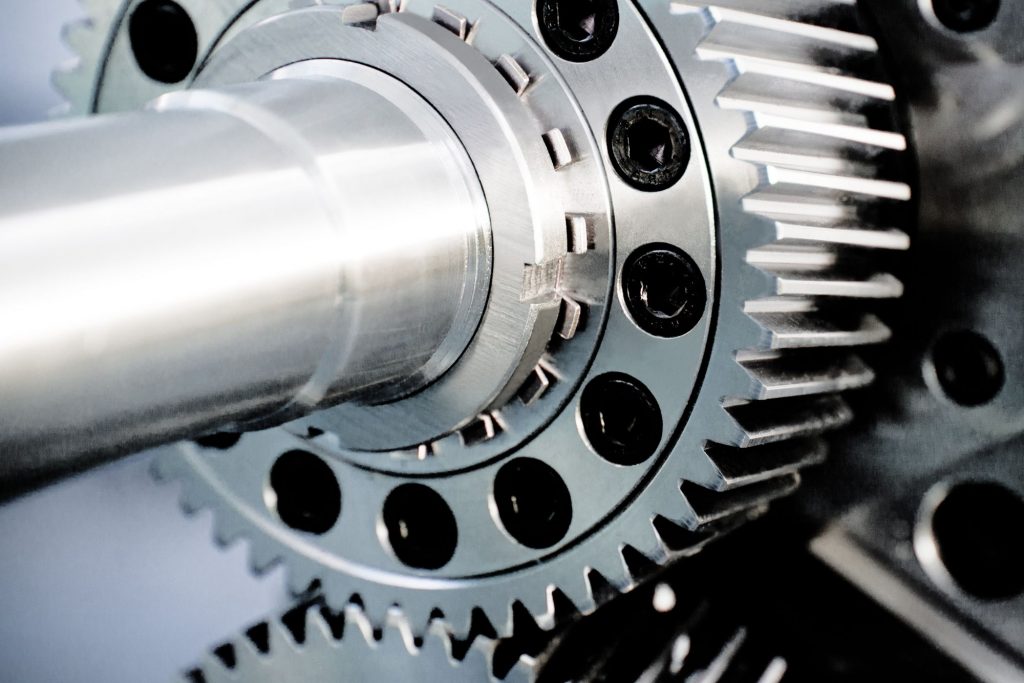

High tech - ipp Pump Products

ipp Pump Products GmbH fertigt nach modernsten Verfahren mit Maschinen der Zerspanungstechnik alle wichtigen Bauteile der Pumpe aus dem Vollen. Produktberührte Teile werden aus hochwertigstem Walzstahl gefertigt. Die Summe einzigartiger Details in der Getriebekonstruktion entscheiden über eine erstklassige Performance unserer Drehkolbenpumpen. Weltweit einzigartig: Im Basisdesign kann die Premiumlobe Drehkolbenpumpe für Differenzdrücke bis 80 bar eingesetzt […]

ipp Pump Products - Worldwide

ipp is the technologically leading manufacturer of rotary lobe pumps. Renowned customers all over the world have already chosen our premium products Made in Germany. Based in Germany, ipp Pump Products GmbH delivers standard and individual solutions at the highest level.