ipp Pump Products is represented at the world's leading trade fair for the process industry.

Visit us at the ACHEMA in Frankfurt am Main.

From June 10-14, 2024 in hall 8.0 | booth E80

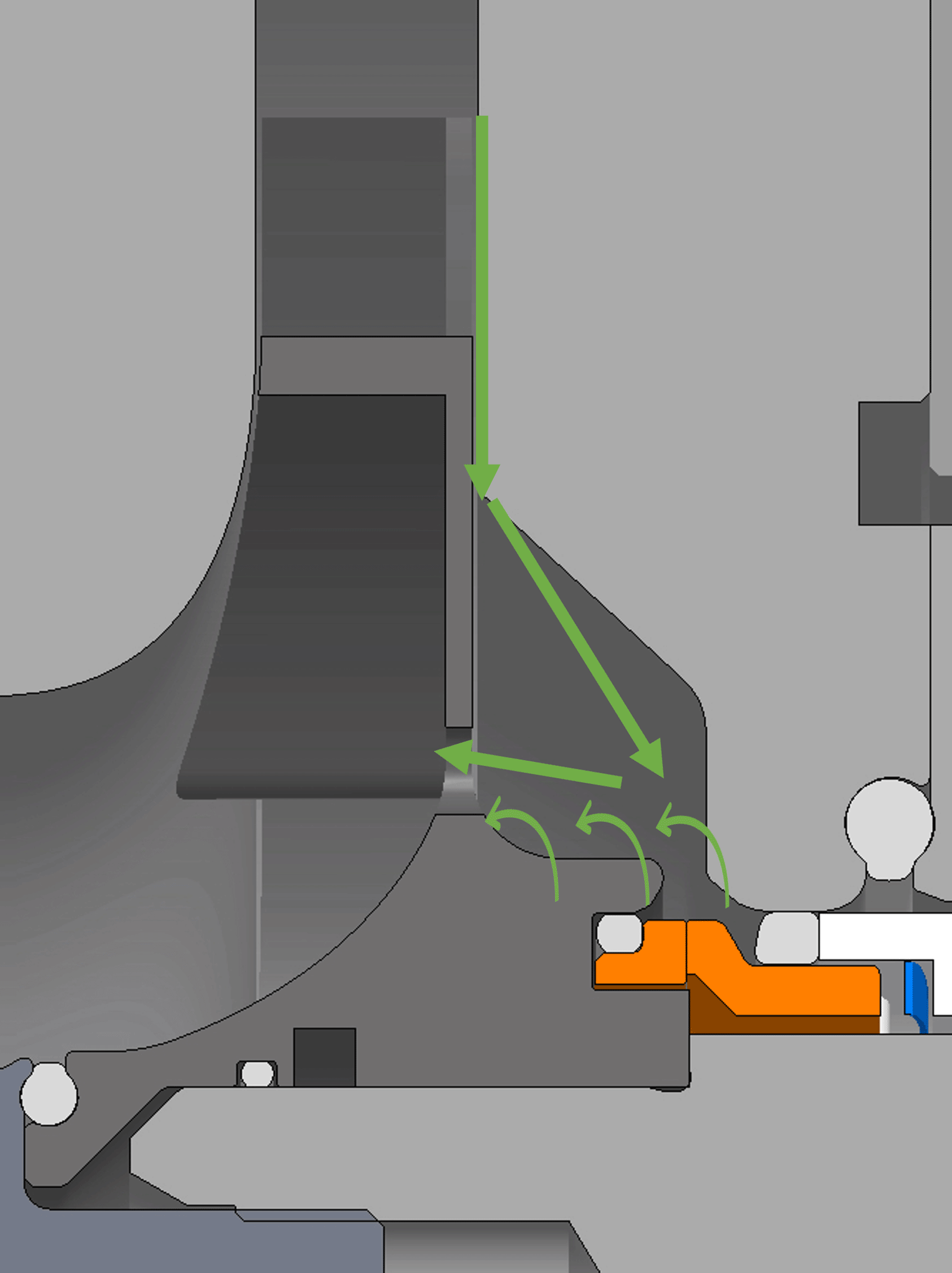

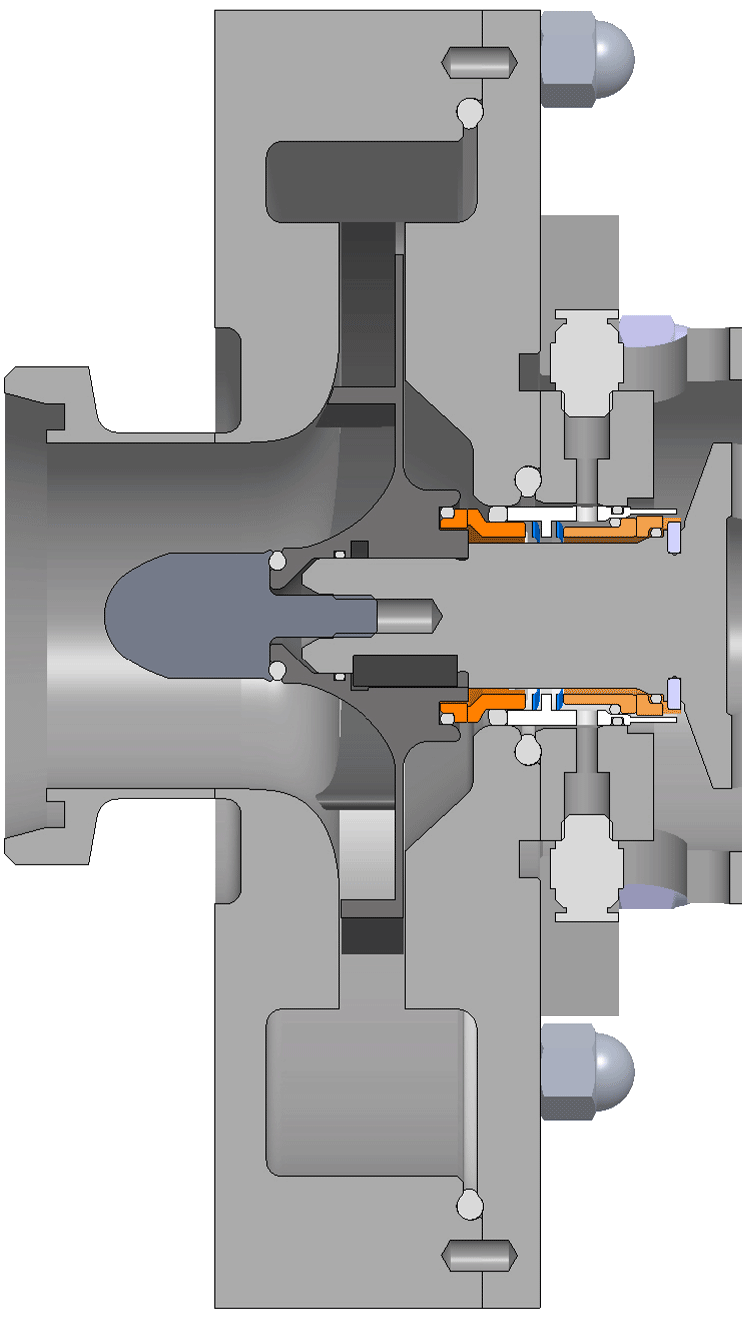

We look forward to welcoming you at the ipp Pump Products booth at ACHEMA. Discover why our premium centrifugal pumps and Rotary lobe pumps in the Chemistry, pharmaceutical industry and Biotechnology are leading. Benefit from the opportunity to talk to our founder Dipl.-Ing. Thomas Moldenhauer and our team of experts.

Experience German engineering and pioneering pump technology that will increase your process efficiency and set new standards in your production.

We look forward to exchanging ideas with you.

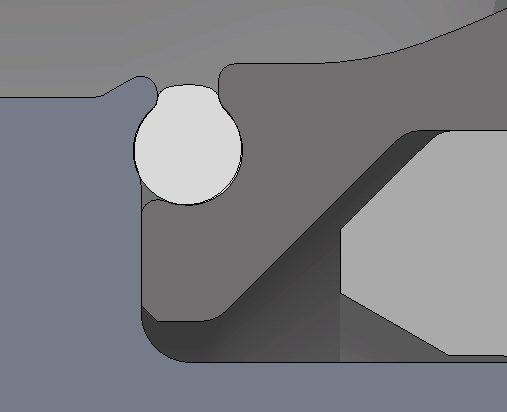

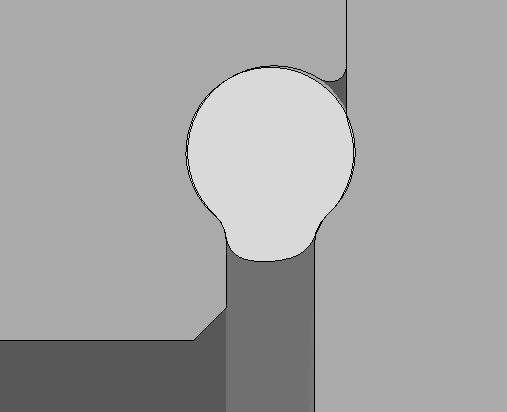

O-ring cover housing

O-ring cover housing