Job as a technicianFocus on mechanical engineering in Bersenbrück

Technician (m/f/d)

We are the leading manufacturer of rotary lobe pumps in terms of technology. Our premium products are used worldwide. We give our customers the decisive edge they need to succeed—and we also believe it is important for our team to recognize and promote potential.

We are looking for you as

Technician (m/f/d)

Place of work:

Bersenbrück

Working hours:

Full-time (40 hours/week)

Entry date:

as of now

Your tasks:

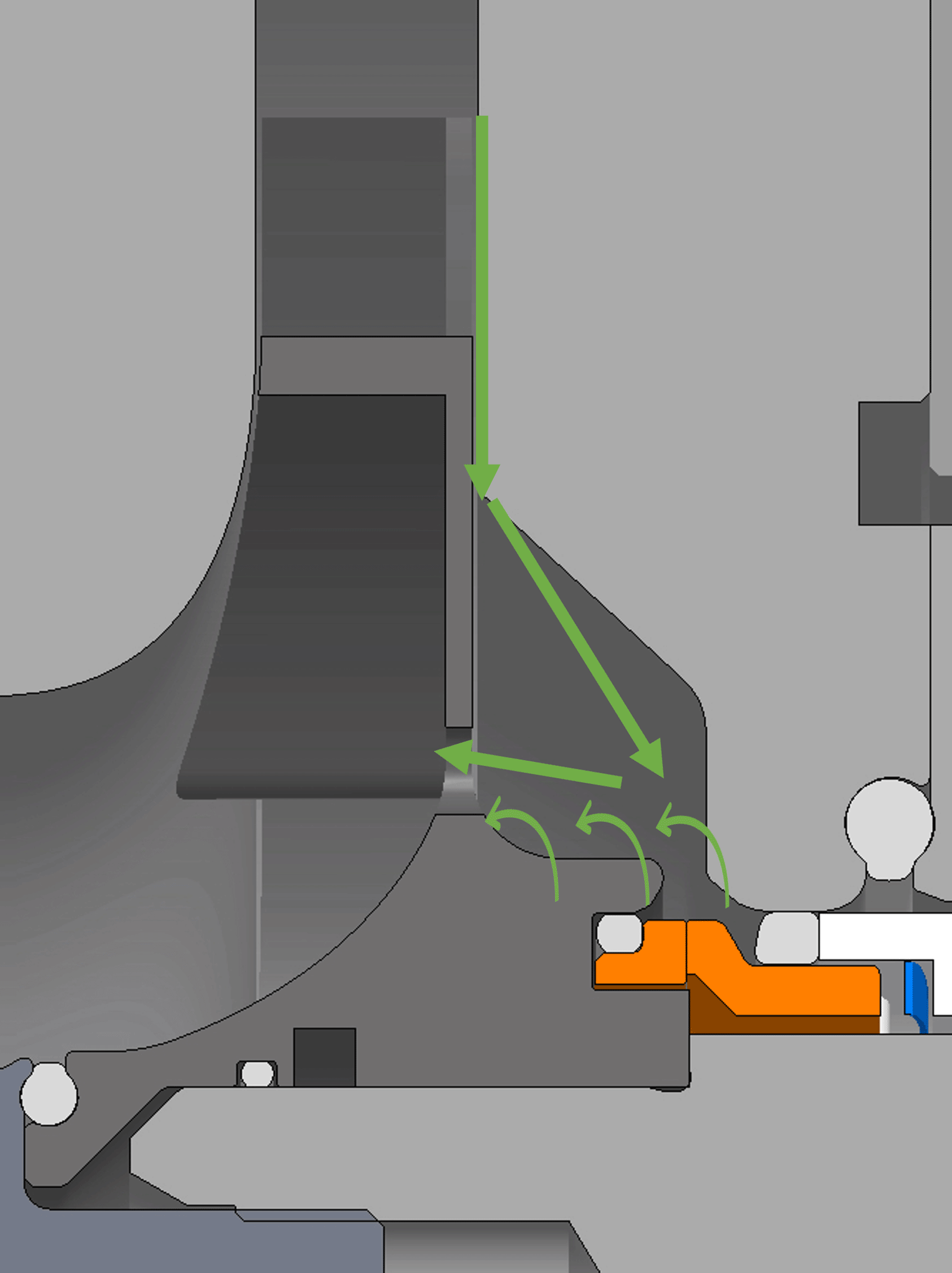

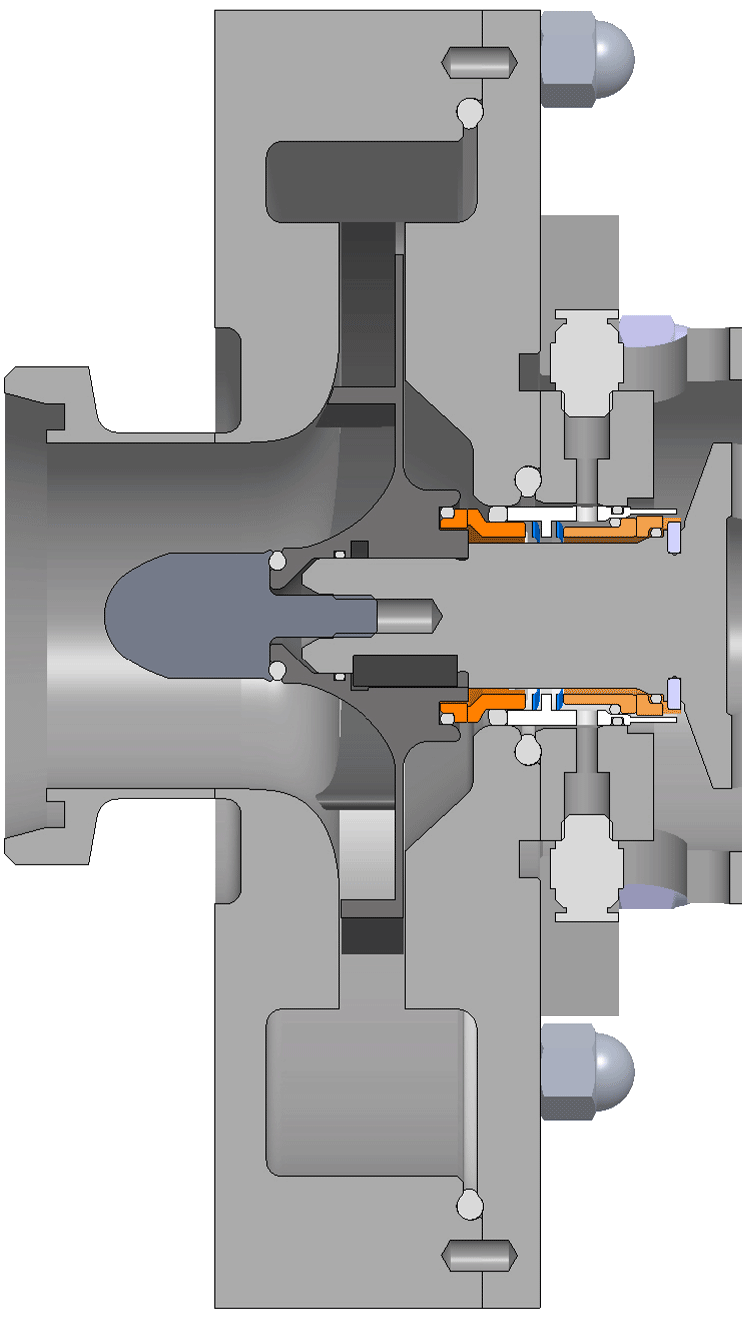

- Independent assembly of stainless steel pumps according to design specifications (mechanical, pneumatic, hydraulic)

- Independent testing and commissioning

- Fault analysis and repair

- Order picking

- Carrying out coordination and optimization work

- Participation in project and design discussions

- Compliance with quality, cost, and deadline specifications

Your profile:

- Completed technical training

- Ideally, experience in the metalworking industry

- Ability to work independently and strong team orientation

- High level of commitment and ability to work independently

- Strong quality awareness

- Confident communication skills in German

What we offer:

- Varied tasks

- Top salary

- Flat hierarchies

- Regular feedback

- A close-knit team

- Free drinks at work

- Regular company events

Our benefits:

- HanseFit

- EdenRed - credit card

- JobBike

Betriebliche Altersvorsorge

Contact:

Fits, wobbles and has air? That makes us happy!

Apply directly by e-mail to sstraub@pump-products.de. sandra.straub@psgdover.com.

If you have any questions, we are here for you!

Contact: Sandra Straub

Phone: +49 5439 80 921-0

Mail: sandra.straub@psgdover.com

ipp Pump Products GmbH

Feldmühlenweg 6-10

D-49593 Bersenbrück

Contact person

Sandra Straub

Executive Assistant

+49 5439 80921-0

Sandra Straub call directly.

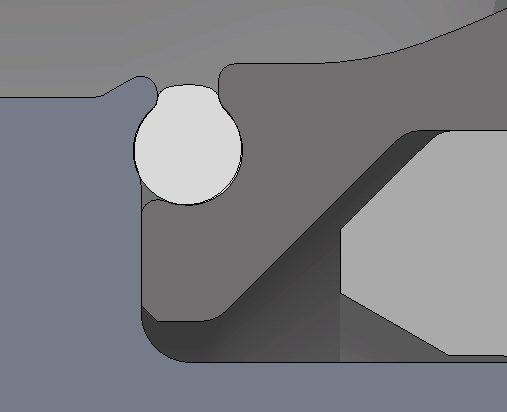

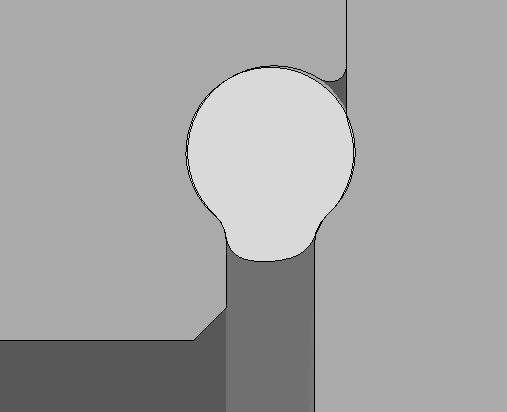

O-ring cover housing

O-ring cover housing