Job as an engineerfor design and development in Bersenbrück

Engineer for design and development (m/f/d)

ipp Pump Products GmbH is one of the premium manufacturers of stainless steel pumps for the food, pharmaceutical, and cosmetics industries. Based in Bersenbrück, we produce for the global market in the premium segment.

We are looking for you as

Engineer for design and development (m/f/d)

Place of work:

Bersenbrück

Working hours:

Full-time (40 hours/week)

Entry date:

as of now

Your tasks:

- CAD design & order processing, research and development, sales support

- Routine test bench runs (new pumps, repairs, reports, documentation, evaluations, and much more)

- Field trials

- All types of tests:

- Hydraulic and mechanical performance limits

- Service life determinations

- Determining wear profiles

- Pump tests with product samples, determining pump behavior

- Thermal tests

- Materials, corrosion behavior, tribology, e.g.

- Designing pump test benches for routine testing and experiments

- Budgeting, planning, and control

Your profile:

- University degree/bachelor's degree in design engineering, mechanical engineering

- Initial experience in research and development

- Basic knowledge of CAD (computer-aided design) systems

- English language skills are desirable

- Driving licence

What we offer:

- A permanent job

- Varied tasks

- Top salary

- Flat hierarchies

- Regular feedback

- A close-knit team

Our benefits:

- HanseFit

- EdenRed - credit card

- JobBike

- Company pension scheme (after probationary period)

Contact:

Fits, wobbles and has air? That makes us happy!

Apply directly via our Contact form or by email to sandra.straub@psgdover.com.

If you have any questions, we are here for you!

Contact: Sandra Straub

Phone: +49 5439 80 921-0

Mail: sandra.straub@psgdover.com

ipp Pump Products GmbH

Feldmühlenweg 6-10

D-49593 Bersenbrück

Contact person

Sandra Straub

Executive Assistant

+49 5439 80921-0

Sandra Straub call directly.

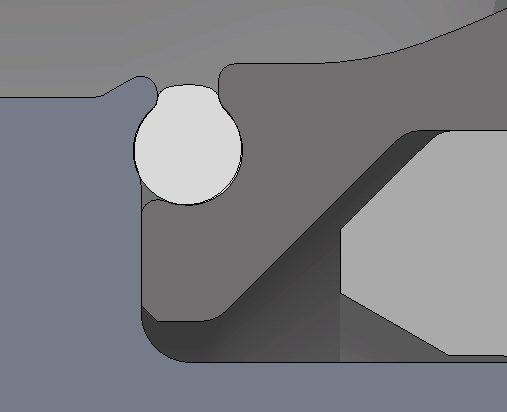

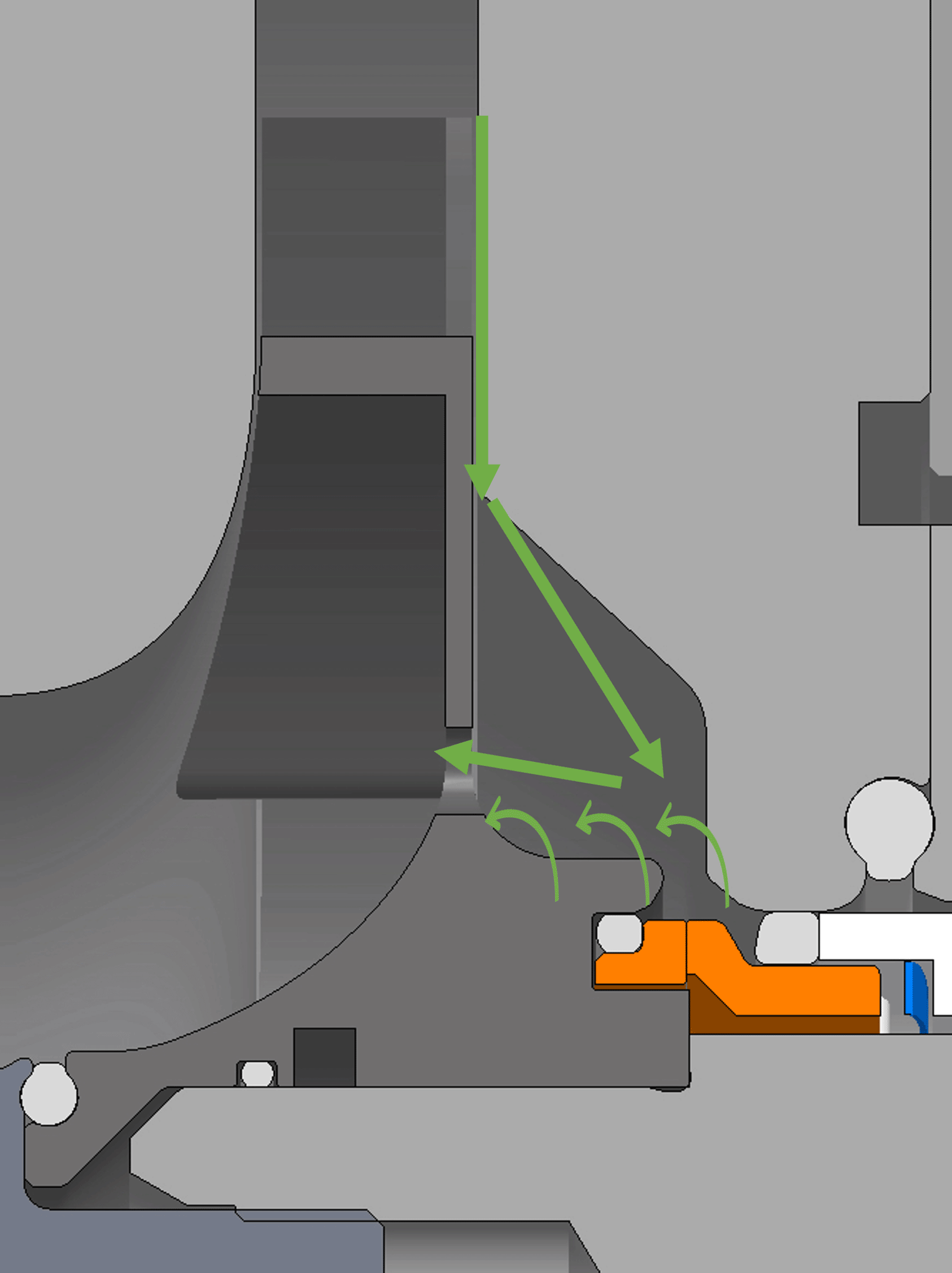

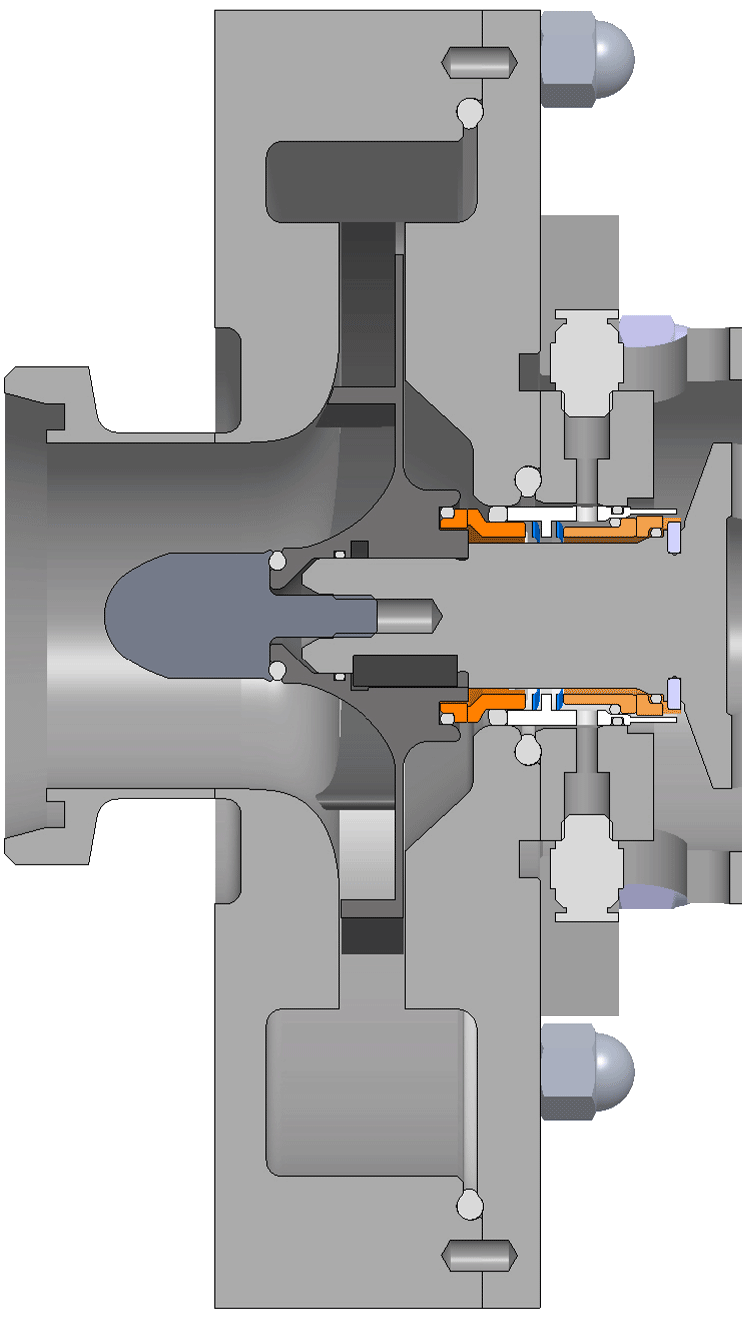

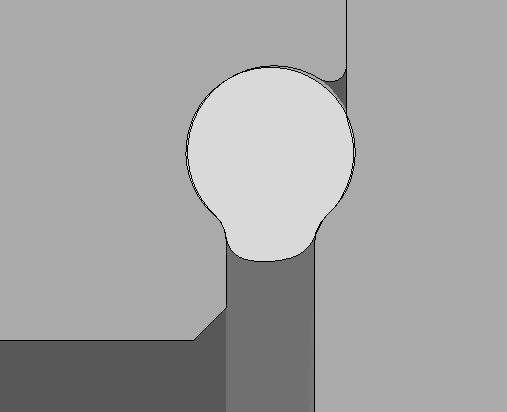

O-ring cover housing

O-ring cover housing