Contact

Contact ipp Pump Products GmbH

Are you interested in our pumps or do you need spare parts? Then get in touch with us. We look forward to receiving your enquiry and will get back to you as soon as possible.

Headquarters in Bersenbrück

ipp Pump Products GmbH

Feldmühlenweg 6-10

D-49593 Bersenbrück

Fon +49 5439 80921-0

Fax +49 5439 80921-20

E-Mail: info@pump-products.de

Contact us

Get in touch with our experts. Our team will advise you on the specification of our products and provide quotations for pumps from ipp Pump Products.

Sandra Straub

Executive Assistant

Dipl.-Ing. (FH)

Walerij Stein

Technical Management /

Construction /Quality Manager

B.Sc.

Matthias Pohlkamp

Applications expert/ Sales

Bengt Nordmann

Applications expert

International distribution

+49 5439 80921-0

bengt.nordmann@psgdover.com

Christiane Schimpfky

Shipping & Distribution

Maik Becker

Purchase

M.Sc.

Christoph Kuhlmann

Development Engineer

State-certified Tech.

Daniel Wellbrock

Development & Construction

Christoph Holtkemper

Order processing

Markus Bünnagel

Order processing

Annalena Hahn

Commercial clerk

Lea Welp

Commercial clerk

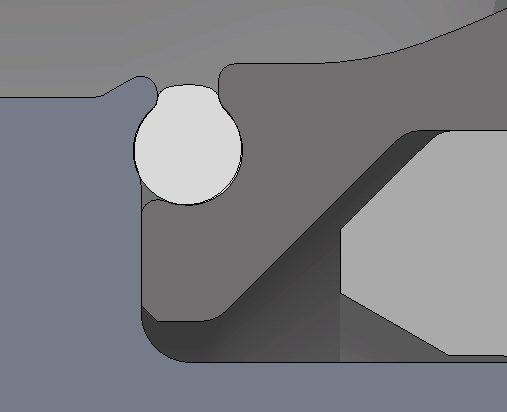

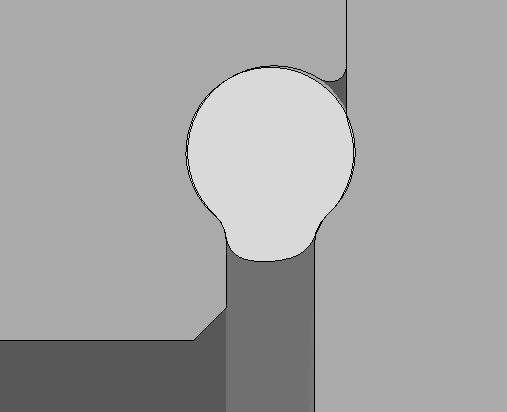

O-ring cover housing

O-ring cover housing