After Sales

Wear and spare parts

We store several thousand spare parts for you. By means of the pump serial number or your order number we can quick and easily replace the missing part for you - our stock keeping allows a reliable provision of all important wear and tear parts. Within Germany or neighbouring EU countries we are able to supply - depending on shipping mode - in most cases already within 24 h.

Our services:

- Damage analysis and repair concept

- Binding estimate of cost

- Short term repair in the factory

- Use of original parts

- Collection and Supply service

- Pumps for rental or loan for the time of repair available upon request.

Repairs

Repair on site

If a pump is not available for a repair in our factory our service team offers quick assistance. Depending on the job site we can be at your assistance within 2 h and carry out a temporary repair. We can even offer you a remote support over the phone assisted by videos and pictures.

Repair inhouse

A reconditioned pump reaches the quality of a new pump which means a long term maintenance of value. The repair is carried out in our ipp workshop by experienced technicians and engineers. Each reconditioned pump is measured and checked on the test stand before shipment.

For the protection of our employees and operating equipment, please send us the signed clearance certificate . Due to legal regulations, we need this before we process your order. Thank you very much.

Product training

Do you require an advice regarding maintenance or cleaning of your pump? Our professional engineers at ipp Pump Products GmbH visit you and offer product trainings on site. On the basis of user examples you learn directly in practice to operate the pump correctly or carry out easy repairs independantly and correctly. This saves cost, reduces wear and thus follows the principle of sustainability. Besides concrete know-how, our well skilled instructors will also show you tips and tricks from practice about information regarding evaluation of damage and wear and tear. Furthermore:

- Company's presentation

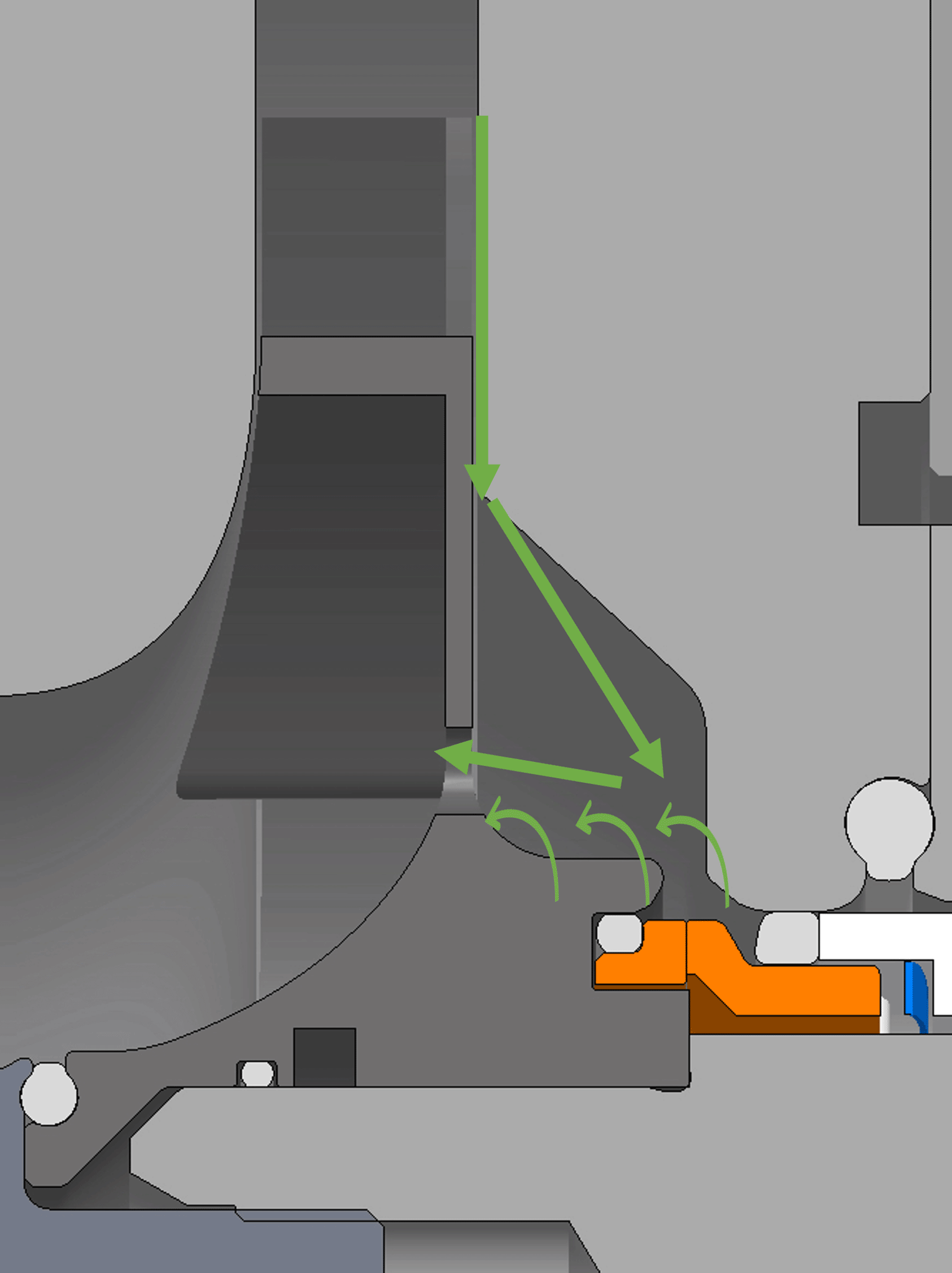

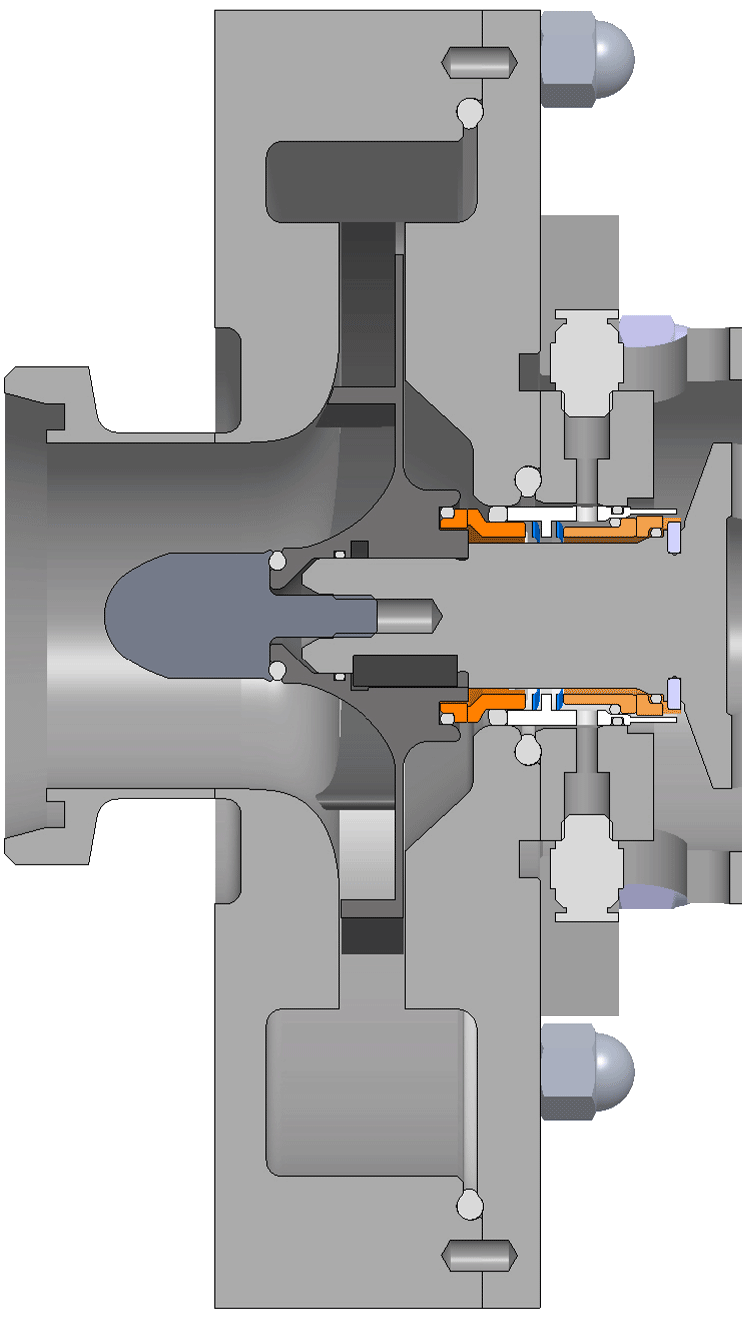

- Structure and operating principle of the ipp rotary lobe pump.

- Maintenance: Procedure of disassembly and repair.

- Functional test: important points?

- Determination of failure causes: sources of error and wear patterns and their analysis.

Spare parts & repairs

Please contact our specialists. Our team will advise you on the design of plants, process engineering processes and provide you with quotations for pumps, systems and plants from ipp Pump Products.

Your contact persons

Benjamin Klein

On site assistance

+49 5439 80921-0

B.Sc. Michael Krone

Technical support

+49 5439 80921-0

michael.krone@psgdover.com

Christiane Schimpfky

Shipping & Distribution

+49 5439 80921-0

christiane.schimpfky@psgdover.com

Call now directly

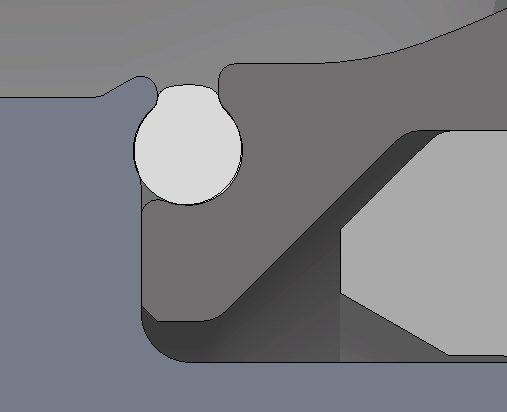

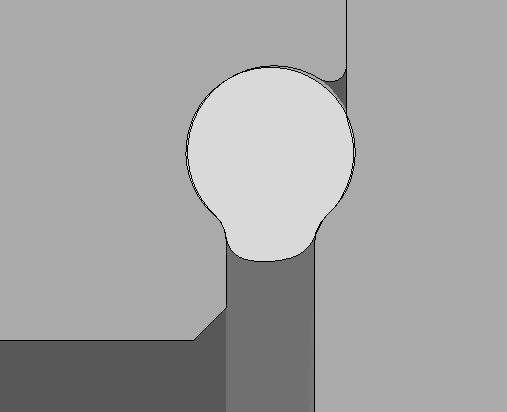

O-ring cover housing

O-ring cover housing